6

Heavy Cutting Pressure Control

Dial is located on

lower left of assembly. It is used to adjust cutting

pressure of honing stone where heavy stock removal

is required. Use in conjunction with Feed Dial and

Honing Dial to ensure maximum efficiency.

Spindle Drive Motor

is located on top of assembly.

It supplies power for honing operation.

4. COOLANT PUMP SYSTEM. Applies coolant to

workpiece and mandrel. Three independently controlled

nozzles are easily positioned to assure an even flow of

coolant through workpiece being honed and over full

length of mandrel. Two nozzles are used to feed

coolant to each end of mandrel. The third may be

used to feed additional coolant to either end of

workpiece, for externally cooling workpiece or for

flushing workpiece before gaging. Coolant Pump

System is located inside top left of machine

(see

Figure 2-4)

. It consists of following components:

Centrifugal Coolant Pump is located inside coolant

reservoir and is driven by spindle motor.

Coolant Flow Control Manifold

is located on left

front of machine. It provides independent regulation

of coolant flow to each

Coolant Nozzle

through

Total Volume Control Valve

and

Individual Coolant

Nozzle Control Valves

. Total volume valve is used

to turn on and off supply of coolant, eliminating

readjustment of individual coolant nozzle control

valve setting.

Coolant Nozzles

attaches to

Coolant Support Arm

located on front of machine in Movable Tray.

Nozzles supply coolant to workpiece and mandrel.

Three independently controlled coolant nozzles are

easily positioned to assure an even flow of coolant

through workpiece and over full length of mandrel.

WARNING

Clean Coolant spills. Coolant can be slick and can

provide a personal fall hazard.

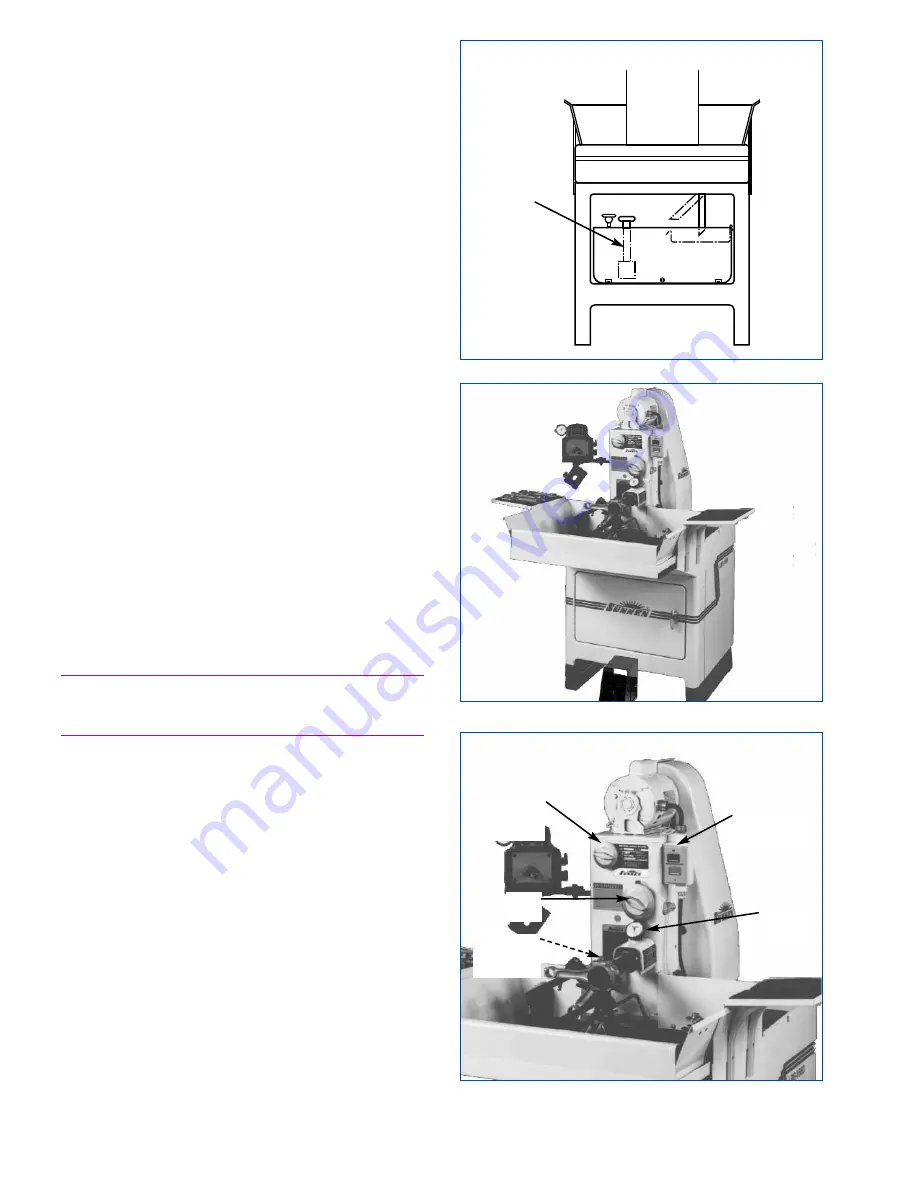

6. ELECTRICAL COMPONENTS Sunnen Honing

Machine is available in 110/230 Volt, single phase,

60 Hz.; or 220//380/440 Volt, 50 Hz, 3 Phase. Its

major components are as follows

(see Figure 2-5)

:

Operator

Controls

are located on right front of Hone

Head Assembly.

Main Power Disconnect is located on left side of

Belt Guard. Electrical power to machine is

controlled by Main Power Disconnect.

7. ACCESSORIES The following items are supplied

as standard equipment with your machine:

Hex Key Wrenches, Metric Wrenches, and T-Wrench.

MAN-700 Diamond Dresser. Used to break glaze on

aluminum oxide and silicon carbide honing stones.

Manual Torque Support. Adjustable support used to

absorb torque from holding fixture (or workpiece)

when honing manually. Manual Torque Support

Arm. Used to hold Manual Torque Support when

manually honing.

FIGURE 2-4, Coolant Pump Assembly

COOLANT

PUMP

FIGURE 2-5, Electrical Components

FIGURE 2-6, Controls

CONTROLS

(START/STOP)

LIGHT

PRESSURE

CONTROL

FEED

DIAL

HEAVY-

PRESSURE

CONTROL

HONING

DIAL

Summary of Contents for LBB-1660

Page 8: ...NOTES viii...

Page 34: ...NOTES 26...

Page 38: ...NOTES 30...

Page 40: ...NOTES 32...

Page 44: ...NOTES 36...

Page 45: ...37 APPENDIX E DECLARATION OF CONFORMITY CE PAGE 1 OF 2 SAMPLE CE DOCUMENT...

Page 46: ...38 APPENDIX E DECLARATION OF CONFORMITY CE PAGE 2 OF 2 SAMPLE CE DOCUMENT...