Section 6

ES-8 MOBILE APPLICATION MANUAL R00

23

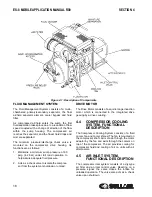

MAINTENANCE

6.1

INTRODUCTION

As you proceed in reading this section, it will be easy

to see that the maintenance program for the air

compressor is quite minimal. The Supervisor

monitors the status of the separator element. When

maintenance to this device is required, the

Supervisor will display the appropriate maintenance

message and flash the location LED on the graphics

map as a visual reminder. See instructions for each

item in

Section 6.6: Parts Replacement And

6.2

DAILY OPERATION

Prior to starting the compressor, it is necessary to

check the fluid level in the sump. Should the level be

low, simply add the necessary amount. If the addition

of fluid becomes too frequent, a minor problem has

developed which is causing this excessive loss. See

under Excessive Fluid Consumption

for a probable cause and remedy.

After a routine start has been made, a general check

of the overall compressor should bemade to assure

that the compressor is running properly.

6.3

MOTOR BEARING

LUBRICATION

See motor manufacturer’s lubrication instructions.

6.4

FLUID FILTER

MAINTENANCE

Replace the fluid filter element under any of the

following conditions:

1. As recommended in the Lubrication Guide in

the Specification Section, and below.

2. Every year.

3. Every fluid change.

WARNING

Before doing compressor maintenance, dis-

connect compressor from power source

and lock out power source. Isolate com-

pressor from line pressure by closing rec-

ommended discharge shut-off valve and

releasing all internal pressure from com-

pressor.

WARNING

DO NOT remove caps, plugs, and/or other

components when compressor is running

or pressurized. Stop compressor and

relieve all internal pressure before doing so.

WARNING

Before doing compressor maintenance, dis-

connect compressor from power source

and lock out power source. Isolate com-

pressor from line pressure by closing rec-

ommended discharge shut-off valve and

releasing all internal pressure from com-

pressor.

WARNING

Fluid filter has internal bypass. DO NOT

SUBSTITUTE.

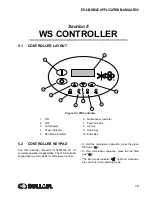

Summary of Contents for 30XH

Page 10: ...NOTES 10 ...

Page 22: ...NOTES 22 ...

Page 33: ...NOTES 33 ...

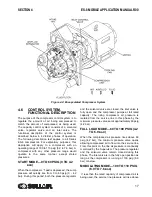

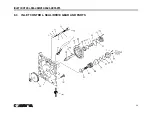

Page 34: ...INLET CONTROL SEAL DRIVE GEAR AND PARTS 34 8 3 INLET CONTROL SEAL DRIVE GEAR AND PARTS ...

Page 36: ...MOTOR COUPLING FAN AND PARTS 36 8 4 MOTOR COUPLING FAN AND PARTS ...

Page 40: ...COMPRESSOR COOLER SYSTEM AND PARTS 40 8 6 COMPRESSOR COOLER SYSTEM AND PARTS ...

Page 42: ...PNEUMATIC CONTROL SYSTEM AND PARTS 42 8 7 PNEUMATIC CONTROL SYSTEM AND PARTS ...

Page 44: ...CONTROL STARTER MFV 44 8 8 CONTROL STARTER MFV ...

Page 46: ...DECAL GROUP 46 8 9 DECAL GROUP ...

Page 48: ...DECAL GROUP 48 8 9 DECAL GROUP CONTINUED ...

Page 50: ...WIRING DIAGRAM FULL VOLTAGE STANDARD 50 8 10 WIRING DIAGRAM FULL VOLTAGE STANDARD ...

Page 51: ...NOTES 51 ...