ES-8 MOBILE APPLICATION MANUAL R00

SECTION 6

26

5. Reinstall the cap. Hand tighten using a

100mm maximum length, 6mm diameter pin

in the radially drilled hole.

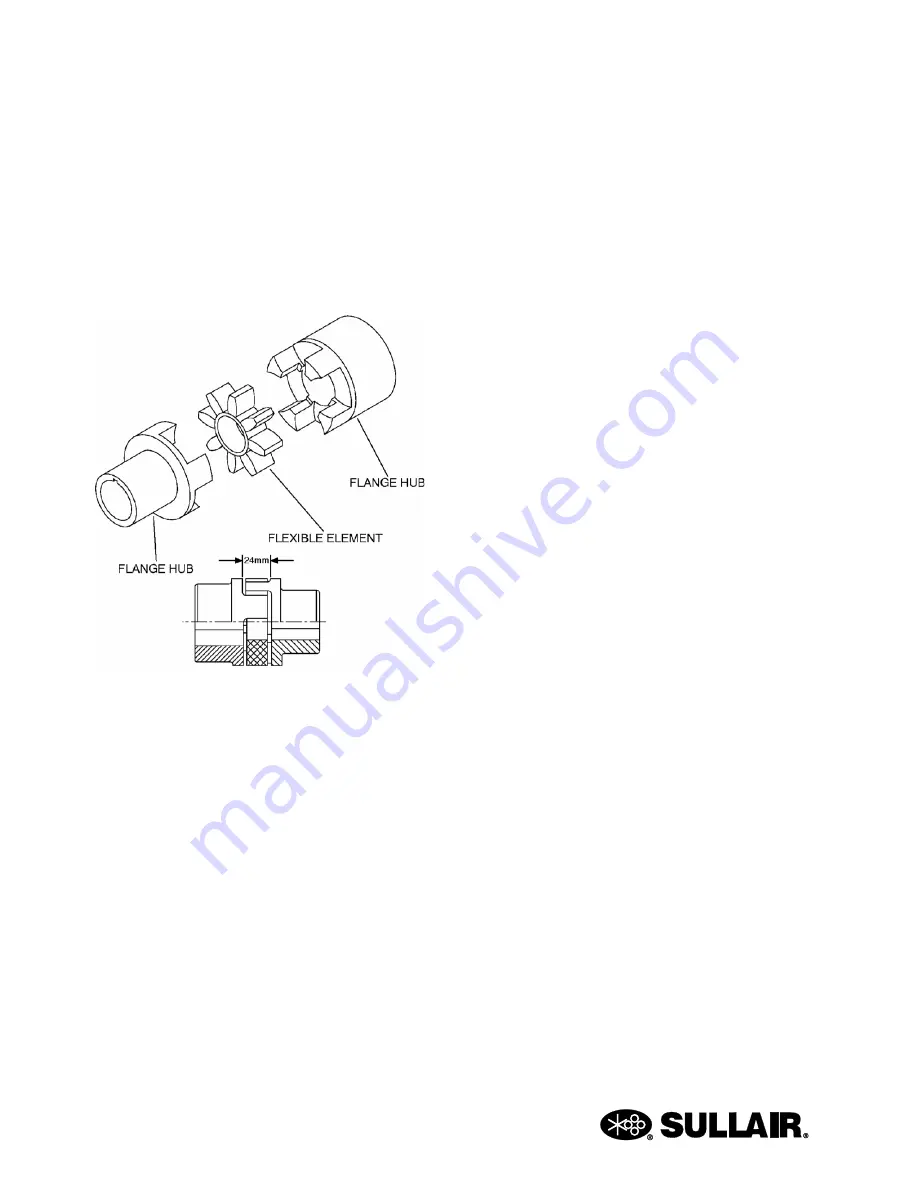

DRIVE COUPLING INSTALLATION

. For coupling installation the tools

required will be one set of Allen wrenches. All ES-8

compressors are flange-mounted to the motor

making them self-aligning, eliminating the need for

alignment procedures. Proper hub separation is s

hown in

.

CONTROL SYSTEM ADJUSTMENT

All components in the Control System are designed

and manufactured to close tolerances to help

eliminate any need for adjustments.

DANGER

DO NOT touch the electrical contacts, terminal or

leads with any part of the body or any uninsulated

metallic object. Severe electrical shock may occur.

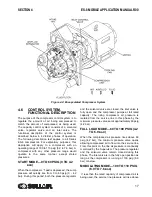

PRESSURE VALVE ADJUSTMENT

If pressure valve adjustment is required the

adjustment procedure below should be followed:

1. Start compressor.

2. Lower line pressure (P2) until machine goes

on load.

3. Loosen hex nut on the regulator valve to

adjust machine modulation. Adjust screw in

or out until on load/off load modulation of

compressor takes place.

4. Close service valve downstream from

receiver tank. The pressure will increase

depending on the regulator valve adjustment

screw setting. Adjust screw until line pres-

sure (P2) rises to the Supervisor II prepro-

grammed off load setting. Tighten hex nut.

5. Open service valve and observe correct on

load/ off load modulation.

Figure 6-4: Hub Separation

Summary of Contents for 30XH

Page 10: ...NOTES 10 ...

Page 22: ...NOTES 22 ...

Page 33: ...NOTES 33 ...

Page 34: ...INLET CONTROL SEAL DRIVE GEAR AND PARTS 34 8 3 INLET CONTROL SEAL DRIVE GEAR AND PARTS ...

Page 36: ...MOTOR COUPLING FAN AND PARTS 36 8 4 MOTOR COUPLING FAN AND PARTS ...

Page 40: ...COMPRESSOR COOLER SYSTEM AND PARTS 40 8 6 COMPRESSOR COOLER SYSTEM AND PARTS ...

Page 42: ...PNEUMATIC CONTROL SYSTEM AND PARTS 42 8 7 PNEUMATIC CONTROL SYSTEM AND PARTS ...

Page 44: ...CONTROL STARTER MFV 44 8 8 CONTROL STARTER MFV ...

Page 46: ...DECAL GROUP 46 8 9 DECAL GROUP ...

Page 48: ...DECAL GROUP 48 8 9 DECAL GROUP CONTINUED ...

Page 50: ...WIRING DIAGRAM FULL VOLTAGE STANDARD 50 8 10 WIRING DIAGRAM FULL VOLTAGE STANDARD ...

Page 51: ...NOTES 51 ...