65

Group 2 Gear Motors Technical Information

System Requirements

Hydraulic fluids

Ratings and data for gear motors are based on operating with premium hydraulic fluids containing

oxidation, rust, and foam inhibitors. These fluids must

possess good thermal and hydrolytic

stability to prevent wear, erosion, and corrosion of internal components. They include:

Hydraulic fluids following DIN 51524, part 2 (HLP) and part 3 (HVLP) specifications•

API CD engine oils conforming to SAE J183•

M2C33F or G automatic transmission fluids•

Certain agricultural tractor fluids•

Use only clean fluid in the motor and hydraulic circuit.

Caution

Never mix hydraulic fluids.

Please see Sauer-Danfoss publication

Hydraulic Fluids and Lubricants Technical Information,

520L0463

for more information. Refer to publication

Experience with Biodegradable Hydraulic

Fluids Technical Information, 520L0465

for information relating to biodegradable fluids.

Temperature and viscosity

Temperature and viscosity requirements must be concurrently satisfied. Use petroleum / mineral-

based fluids.

High temperature l

imits apply at the inlet port to the motor. The motor should run at or below the

maximum continuous temperature. The peak temperature is based on material properties. Don’t

exceed it.

Cold oil,

generally, doesn’t affect the durability of motor components. It may affect the ability of oil

to flow and transmit power. For this reason, keep the temperature at 16 °C [60 °F] above the pour

point of the hydraulic fluid.

Minimum

(cold start)

temperature

relates to the physical properties of component materials.

Minimum viscosity

occurs only during brief occasions of maximum ambient temperature and

severe duty cycle operation. You will encounter maximum viscosity only at cold start. During this

condition, limit speeds until the system warms up. Size heat exchangers to keep the fluid within

these limits. Test regularly to verify that these temperatures and viscosity limits aren’t exceeded.

For maximum unit efficiency and bearing life, keep the fluid viscosity in the recommended viscosity

range.

Fluid viscosity

Temperature

Maximum (cold start)

mm

2

/s

[SUS]

1000 [4600]

Recommended range

12-60 [66-290]

Minimum

10 [60]

Minimum (cold start)

°C

[°F]

-20 [-4]

Maximum continuous

80 [176]

Peak (intermittent)

90 [194]

Summary of Contents for M2-H

Page 2: ...2 This page left blank intentionally ...

Page 13: ...13 ...

Page 18: ...18 M2 H Identifying Your Machine Components Location of Tags and PIN Plates ...

Page 19: ...19 SECTION II Description Care and Maintenance ...

Page 31: ...31 SECTION III Set up and Installation of Unit in Detail ...

Page 33: ...33 SECTION IV Operating the M2 Unit ...

Page 41: ...41 SECTION V Troubleshooting the M2 Unit ...

Page 44: ...44 SECTION VI Periodic Maintenance Repair Information ...

Page 49: ...49 SECTION VII OEM Repair Information ...

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ...64 ...

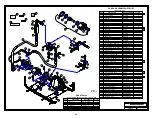

Page 68: ...68 SECTION VIII Parts Manual ...