Page 8 of 14

4. Install the jack so that the unit is parallel to the sidewall of the tire to be lifted. Leave

approximately 3/4" of clearance between tire and jack.

This is very important:

If the unit is misaligned, the tire may hit the axle of the jack and not the

rollers. This may damage the jack and void the warranty.

5. To lift the tire, flip the directional lever up, then place a foot on the pedal, depressing the pedal

with smooth, even strokes. Cycle the pedal until the tire is lifted from the surface one inch or less.

After lifting, the lower the tire is to the ground the more stable the jack will be. After lifting, be sure

to always lock the pin in place before operation. If using more than one jack, repeat the process

on the other tires and maneuver the vehicles as required.

6. To release the jack, pull the pin out from the frame and open the valve by slowly turning the hand-

wheel counter-clockwise. The jack may be removed when the rollers disengage from the tire.

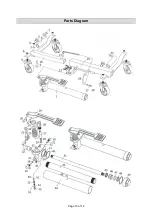

Summary of Contents for 61132

Page 10: ...Page 10 of 14 Parts Diagram ...