7

www.strata.co.nz

www.strata.co.nz

EZIMIG 205 / ADVANCEMIG 255

MMA Welding

Manual Metal Arc (MMA) welding is the most flexible, and

one of the most widely used welding processes. It involves

striking an arc between a coated metal electrode and a

workpiece. The heat of the arc melts the parent metal and

the electrode which together form, on cooling, a single

solid mass. The central metal electrode or core wire acts

as the consumable, providing the filler metal for the weld.

As the weld is laid, the flux coating of the electrode disinte-

grates, giving off vapours that serve as a shielding gas and

providing a layer of slag, both of which protect the weld

area from atmospheric contamination.

MMA welding can be used to join most steels, stainless

steel, cast iron and many non-ferrous metals. For many

mild and high strength carbon steels, it is often the pre-

ferred joining method. Successful results depend on a

number of factors and parameters including correct elec-

trode and size for the job, welding current, arc length, an-

gle of electrode to the job, travel speed and preparation of

the work piece.

Installation and Setup for MMA

(Stick) Welding

1.

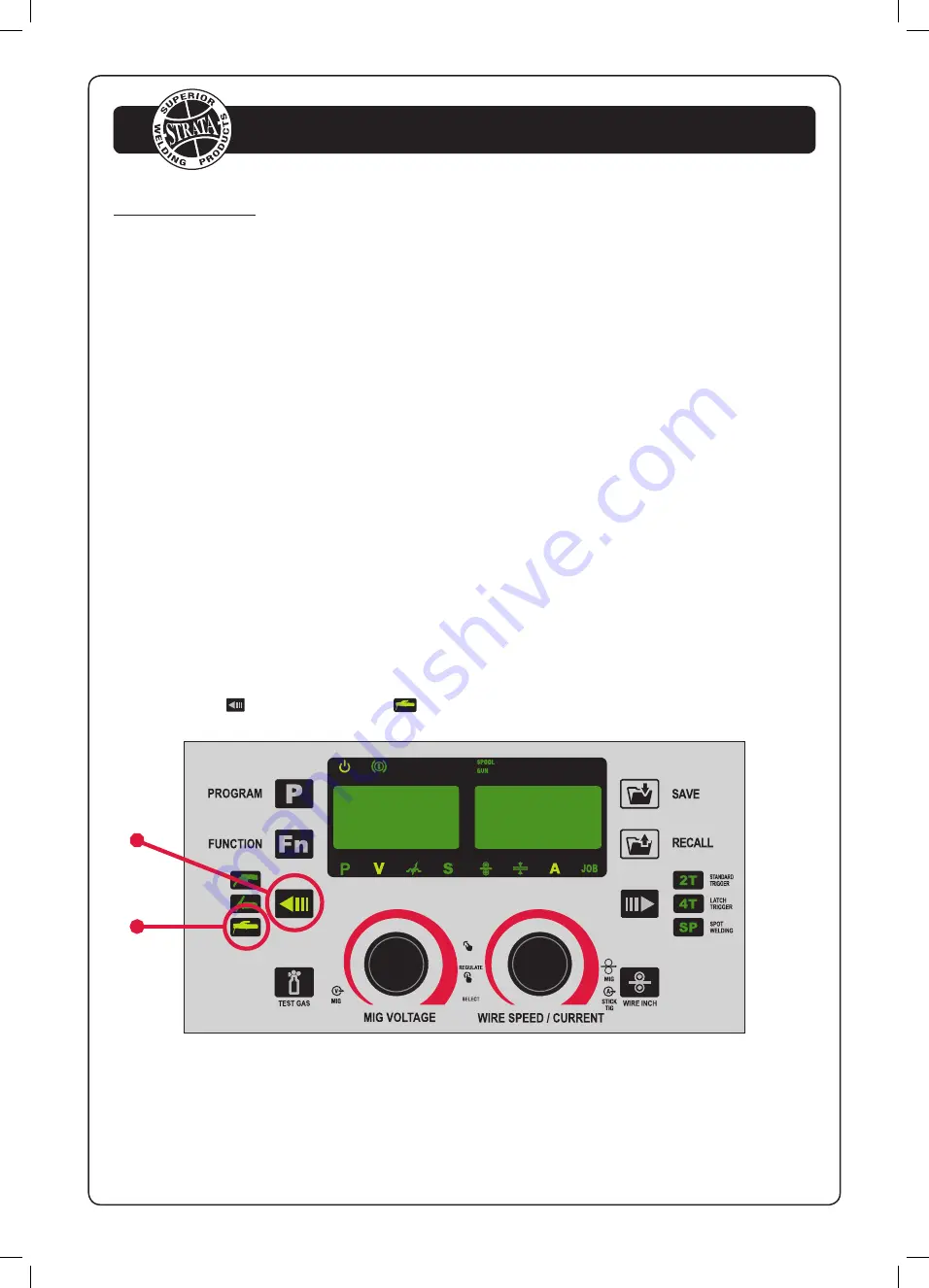

Turn on the power source and select the MMA function

by pressing the button until the MMA light is lit.

should be paid to the polarity. Refer to the electrode

manufacturers’ information for the correct polarity.

DC+

Electrode connected to the (+) output socket, or

DC-

Electrode connected to the (-) output socket.

The Earth clamp quick connector and lead shall be

connected to the opposing polarity.

3. Set the required welding current by rotating the RH

knob relevant to the electrode size and type, as recom-

mended by the electrode manufacturer.

4. Place the electrode into the electrode holder and clamp

tight.

5. Strike the electrode against the workpiece to create an

arc and hold the electrode steady to maintain the arc.

6. Hold the electrode slightly above the workpiece and

travel at an even speed.

7. To finish the weld, break the arc by quickly pulling the

electrode away from the workpiece.

8. Wait for the weld to cool before chipping away the

slag to reveal the welded metal below.

2. Two sockets are available on this welding machine for

MMA welding. For MMA welding the electrode holder

is connected to the Positive socket, while the earth lead

is connected between the workpiece and the negative

socket. However various electrodes require a differ-

ent polarity for optimum results and careful attention

56.O 15O