14

Old mix, or mix that has been stored at too high a tempera-

ture, can result in a fi nished product that is unsatisfactory.

To retard bacteria growth in dairy based mixes, the best

storage temperature range is between 33° to 38°F (0.5°

to 3.3° C).

3.12 OPERATION OF MIX PUMP

The mix pump switch is located on the lower part of the

front panel. When a pump switch is placed in the ON posi-

tion, the mix pump motor will start pumping mix into the

freezing cylinder. When the set pressure is reached, the

mix pump will shut off automatically. When the switch is

placed in the OFF position, the mix pump will not operate.

NOTE

The mix pump motor is equipped with an internal

overload that will “trip”, disabling the pump when

the motor is overloaded. Consult the trouble shoot-

ing section for corrective information. The internal

overload will automatically reset after cooling. If

the condition continues, contact a qualifi ed service

person.

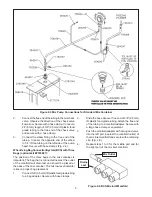

A.

Mix Operation: The peristaltic mix pump contains

one continuous mix pump hose. When looking at

the face of the peristaltic mix pump, the left side

of the hose is the mix intake or pickup. The right

side of the hose is the mix discharge. Mix is drawn

up the pickup side of the hose and transferred

through the discharge side to the machine (Fig.

3-9).

B.

Air Operation: The air compressor operates

whenever the peristaltic mix pump is running.

Air enters through a check valve on the piston

downstroke. The air is discharged through a

second check valve, on the piston upstroke. The

air and mix join at the tee and then travel to the

machine.

C.

The overrun adjustment is preset at the factory.

If an adjustment becomes necessary, refer to

Section 4.

3.13 MIX PUMP CLEANING

NOTICE

Any cleaning procedure must always be followed

by sanitizing before fi lling machine with mix. (Refer

to section 3.3)

The mix pump is approved for CIP (clean in place). It is

thoroughly cleaned when the detergent solution is pumped

through the machine. We recommend completely disas-

sembling the pump and disconnecting tubing every 14

days for inspection of parts to confi rm the CIP has been

properly performed. If any residue is detected, clean or

replace those parts as outlined below.

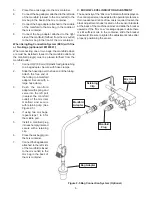

A.

Place the Main Power OFF/ON and Freezing

Cylinder OFF/ON switches in the ON position

and press the CLEAN button. Allow the auger to

agitate for 5 to 10 minutes.

B.

Remove the suction tube from the mix container.

Open the spigot to remove the mix remaining in

the freezing cylinder.

C.

Pump 2 gallons (7.5 liters) of potable water through

machine until the water coming out of the spigot

is clear.

D.

Pump 2 gallons (7.5 liters) of 90° to 110°F (32°C

to 43°C) detergent solution through the machine.

The use of soft water is recommended, along with

dishwashing detergents such as “Joy,” “Dawn,”

or equivalent.

E.

Place the mix pump switch in the OFF position.

Open the spigot to relieve the remaining pressure.

F.

Press the CLEAN button to stop the auger and

place the Main Power OFF/ON and Freezing

Cylinder OFF/ON switches in the OFF position.

Figure 3-9 Mix Pump Hose Routing

Air Line

Mix

Intake

Mix

Discharge

3-way

Tee

Air/mix to

Freeezing

Cylinder