Guide Bars

5

4.1

Overview

4.2

Tools, Servicing Aids

–

Twist drill, 7.5 mm

–

Pin punch, 5 mm

–

Hammer

4.3

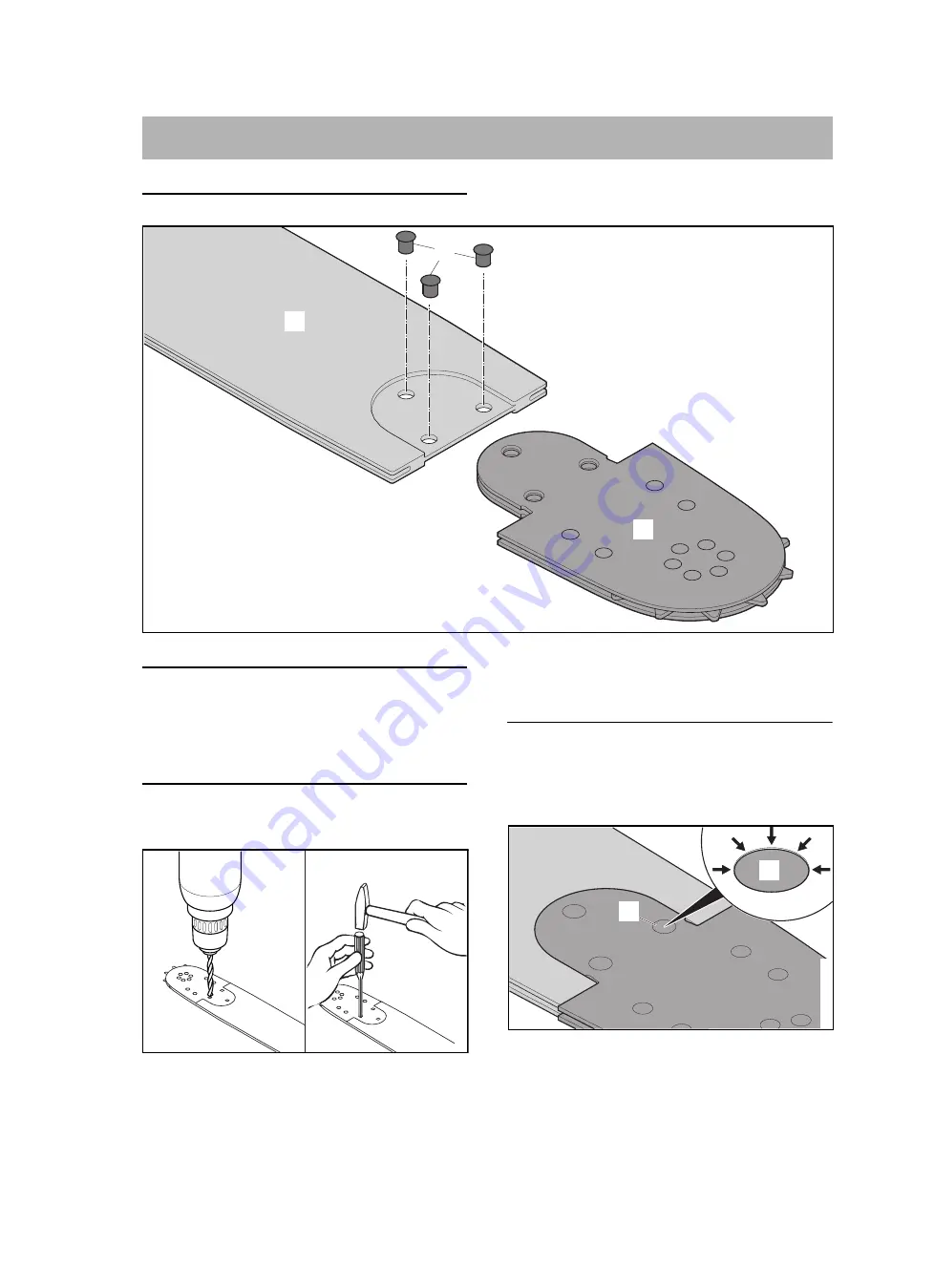

Removing the Guide Bar Nose

The bar nose can be replaced on STIHL Rollomatic ES

and STIHL Rollomatic ES Light guide bars.

N

Center-punch the rivet heads (2).

N

Use a 7.5 mm drill to drill away the heads of the rivets

(2).

N

Knock out the rivets (2) with a 5 mm pin punch.

N

Remove the nose (3) from the guide bar (1).

4.4

Installing the Guide Bar Nose

N

Push the new nose (3) onto the guide bar (1). The

nose may be fitted either way round.

N

Position the nose (3) so that its holes line up with the

holes in the guide bar (1).

N

Fit the countersunk rivets (2) and form their heads.

Each rivet head must completely fill the hole recess

(arrows).

4

Guide Bar Nose

1

3

2

0000-GXX-1601-A0

0000-GXX-2052-A0

2

2

0000-GXX-1602-A0