st

eut

e T

echnol

ogies GmbH & Co. K

G

Brück

ens

tr

aße 91, 32584 Löhne, Germany

, www

.s

teut

e.c

om

2 / 12

//

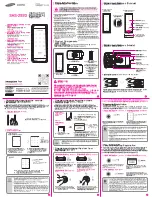

ES 14 AZ Extreme

Montage- und Anschlussanleitung / Türkontakte

Mounting and wiring instructions / Door contacts

Instructions de montage et de câblage / Contacts de porte

Istruzioni di montaggio e di collegamento / Contatti porta

Instruções de montagem e instalação / Contatos de porta

Инструкция по монтажу и подключению / Даерные контакты

English

Use of the mounting and wiring instructions

Target group: authorised and qualified staff.

All actions described in these instructions may only be performed by

qualified persons who have been trained and authorised by the

operating company.

1. Read and understand these mounting and wiring instructions.

2. Comply with the valid occupational safety and accident prevention

regulations.

3. Install and operate the device.

Selection and installation of devices and their integration in control

systems demand qualified knowledge of all the relevant laws, as well

as the normative requirements of the machine manufacturer.

In case of doubt, the German language version of these instructions

shall prevail.

Scope of delivery

1 device, 1 mounting and wiring instructions, carton.

Safety information

=

In this document, the warning triangle is used

together with a signal word to indicate a

hazardous situation.

The signal words have the following meanings:

NOTICE

indicates a situation which may

result in material damage.

CAUTION

indicates a situation which may

result in minor or moderate

injury.

WARNING

indicates a situation which may

result in serious injury or death.

DANGER

indicates a situation which will

result in serious injury or death.

Intended use

The door contacts in series ES 14 AZ Extreme are suitable for moni

toring the door position or the locking mechanism (hook bar)

for elevators.

vorbehalten. steute übernimmt keine Haftung für Empfehlungen, die

durch diese Beschreibung gegeben oder impliziert werden. Aufgrund

dieser Beschreibung können keine neuen, über die allgemeinen steu-

te-Lieferbedingungen hinausgehenden, Garantie-, Gewährleistungs-

oder Haftungsansprüche abgeleitet werden.

Deutsch (Originalbetriebsanleitung)

Installation, mounting, and dismantling

=

DANGER

Live parts.

Electric shock hazard!

Connecting and

disconnecting only to be performed by qualified and

authorised personnel. Connecting and disconnect-

ing only in zero potential state.

Mount the device on an even surface. Please ensure that, even in case

of failure, the position switch cannot be moved from its position. For

protection against unauthorized manipulation, use e.g. one-way safety

screws. These are optionally available. Adjust screws on both sides

using a screwdriver with the same number of turns.

When mounting

the safety switch, observe the requirements of EN 14119, especially

sections 5.1 to 5.4!

Observe the instructions in the standards EN 12100

and EN 14120.

Application and operation

- Use device only within the permitted electrical load limits (see

technical data).

- For short-circuit protection use fuse size 2 A (gG/gN).

- Use device only within the permitted ambient temperature range

(see product label and technical data).

Cleaning

- In case of damp cleaning: Use water or mild, non-scratching,

non-chafing cleaners.

- Do not use aggressive cleaners or solvents.

Maintenance, service, and repair

=

DANGER

Live parts.

Electric shock hazard!

Do not repair de-

fective or damaged devices. Replace them. Do not

rebuild or modify the device in any way.

With rough conditions, we recommend routine maintenance as follows:

1. Check actuator for easy operation.

2. Remove all dirt or particles.

3. Check sealing of the cable or conduit connections.

Disposal

- Observe national, local and legal regulations concerning disposal.

- Recycle each material separately.

N.B.

The electrical connection may only be carried out by authorised per-

sonnel. Do not use the device as mechanical endstop. Any mounting

position is possible. Reconstruction and alterations to the device which

might affect the safety function are not allowed. For the integration of

the device into the entire system, the control category determined in

the risk assessment must be strictly observed and respected.There-

fore, a validation according to EN ISO 13849-2 or EN 62061 is neces-

sary.

Furthermore, the Performance Level according to EN ISO 13849-