14

Manual Proportional Integral Derivative (PID):

Allows the operator to manually input P, I and D parameters into the

controller. These parameters are fixed as long as the controller is in this

mode.

Slo, Nor, or Fast:

Heat/Cool PID quick tune pre-determined parameters. Selectable through

the keypad. See table below for Reference Settings.

Ramp/Soak

The controller is provided with a 16 segment, front programmable

Ramp/Soak feature. Unused alarms can be programmed as a segment.

Caution: Do not operate the auto-tune while a ramp/soak

function is operating.

Ramp/Soak is one of the many features that add process programming

capabilities to the M2B controller. This section will deal only with the

Ramp/Soak programming operation.

Basic Theory Of

Operation Ramp/Soak

The M2B controller is user friendly. It offers an easy way to program a ramp.

Instead of requiring the operator to calculate an approach rate, the M2B

does the calculation automatically. The operator needs to program the

target set point and the time desired to reach that set point. When the ramp

segment is executed by the controller, it calculates the ramp required to

reach the process temperature from starting set point to the programmed

set point in the time allowed.

Dwells (or soaks) are ramp segments with target set point equal to starting

process temperature. This allows for multistage ramps without wasting

intermediate soak steps.

IMPORTANT! Test any program for best results before running production

material.

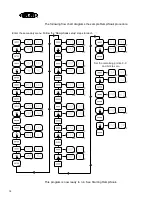

Reference Settings For Manual PID Input

Index

Slow Response

System

Medium Response

System

Fast Response

System

Air

Cooled

Water

Cooled

Air

Cooled

Water

Cooled

Air

Cooled

Water

Cooled

Pb1

Heating Band

12

12

8

8

6

6

Pb2

Cooling Band

12

20

8

12

6

10

db

DeadBand

0

0

0

0

0

0

rES Reset

20.0

15.0

7.0

5.0

3.0

2.0

rtE

Rate

1.67

1.25

0.58

0.42

0.25

0.17

Summary of Contents for M2B

Page 1: ... Rev A ...

Page 49: ...48 ...