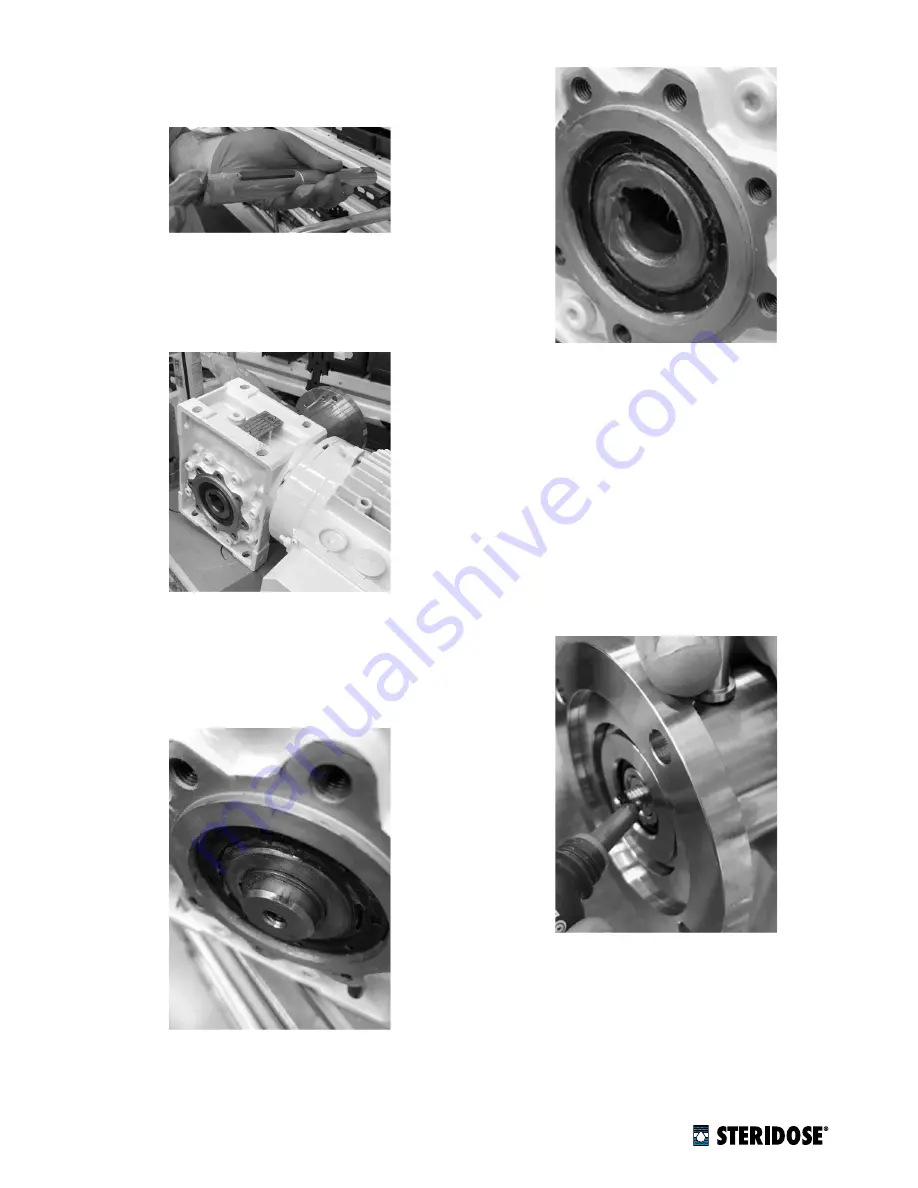

9. Fit the keys in the keyways on the extended shaft and

apply grease (e.g. Chesterton 630 SXCF).

10. Put the drive unit on a flat surface. Verify that the

gearbox’s hollow shaft is completely free of deforma-

tions or burrs. A common file can be used for this

purpose.

11. Verify that the shaft can move smoothly up and down

the gearbox, all the way to the stop provided by the

bottom circlip. If necessary use a file to de-burr and

straighten the hollow-shaft keyway and/or the bot-

tom shaft key.

12. Once the shaft runs smoothly up and down the gear-

box, apply additional grease to the gearbox’s hollow

shaft.

13. Apply a suitable thread-sealant/locking liquid (e.g.

Loctite 243, Loctite 2400) to the Magnet Lowering

Device screw.

14. Screw the Magnet Lowering Device mounting screw

into the bottom end of the shaft and tighten to 17 Nm

(150 in-lb) with assistance of the mounting tool.

6

|

© Steridose

www.steridose.com