3/96

5 - 3

09-282C

SERVICE

section 5

MAINTENANCE AND ADJUSTMENTS

Before inspecting or servicing any part of the

machine, disengage PTO and make sure all

moving parts have come to a complete stop.

The chipping knives and shredding sections are

sharp! Use care when working on machine to

avoid injury.

SHREDDER SECTIONS

The serrated self sharpening shredder sections

are designed to offer long life and can be

reversed if they become dull. To remove or

replace the sections, proceed as follows:

A. Remove discharge shield, discharge screen and

knife access cover.

B. Work with one section shaft at a time. Remove

the #10-24 bolt from the section shaft. The shaft

can be removed through the access hole.

C. Remove sections and section spacers. Be

careful to keep track of the order the spacers

were installed on the shafts so they can be

returned to the original locations. If the spacers

are not installed properly, the rotor will be out of

balance and also will not have proper

shredding action.

D. Reverse or replace sections and reassemble

into the rotor. Reinstall #10-24 bolt and locknut

through spacer and torque to 36 inch pounds.

E. Complete service of all 6 shafts and replace the

knife access cover, discharge screen and

discharge shield.

CLEANING PLUGGED ROTOR

If too large of material or too much material is fed

into

the

chipper/shredder,

it

may

become

plugged. To clear plugged rotor, proceed as

follows:

A. Disengage PTO and stop engine.

B. Remove discharge shield and discharge screen.

C. Clean debris out of the shredding rotor. Turn the

rotor by hand to be sure it is free to rotate.

D. Replace discharge screen and discharge shield.

E. See also Cleaning Plugged Blower.

BELT REPLACEMENT

Check the condition of the double drive belts

every

30

hours

of

operation

or

annually,

whichever occurs first. Only replace belts in sets.

To replace belts proceed as follows:

A. Disengage PTO and stop engine.

B. Remove belt shields.

C. Remove belt idler spring and remove belts from

pulleys.

D. Remove 4 bolts attaching hitch assembly to

main frame and completely remove belts.

E. Place new belts around the hitch frame and

attach the hitch assembly to the main frame.

F. Position belts on the pulleys and attach the idler

arm spring.

G. Check the attachment drive belt and replace if

needed. Replace belt shields.

CLEANING PLUGGED BLOWER

If too much green material is fed into the

chipper/shredder

the

blower

may

become

plugged. To clear the blower, proceed as follows:

A. Disengage PTO and stop engine.

B. Remove blower drive belt guard, and remove

drive belt.

C. Remove the Blower discharge tube.

D. Tilt the blower away from the main frame and

clean debris out of blower housing.

Summary of Contents for CS312

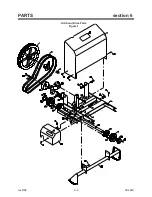

Page 16: ...rev 8 98 6 2 09 282C PARTS section 6 Hitch and Drive Parts Figure 1 ...

Page 18: ...rev 5 00 6 4 09 282C PARTS section 6 Frame Parts Figure 2 ...

Page 20: ...rev 8 98 6 6 09 282C PARTS section 6 Emergency Stop Switch Parts Figure 3 ...

Page 22: ...rev 5 00 6 8 09 282C PARTS section 6 MODEL CS313 Chipper Shredder Blower Parts Figure 4 ...

Page 30: ......