09-282C

5 - 2

3/96

SERVICE

section 5

MAINTENANCE AND ADJUSTMENTS

Before inspecting or servicing any part of the

machine, disengage PTO and make sure all

moving parts have come to a complete stop.

The chipping knives and shredding sections

are sharp! Use care when working on machine

to avoid injury.

SHARPENING CHIPPER KNIVES

It is recommended that the chipper knives are

sharpened every 5 to 15 hours of chipper

operation, depending on the type of wood fed

into the chipper.

To remove the chipper knives for sharpening, first

remove the discharge shield and the discharge

screen. Remove the two 5/16 inch retaining bolts

and pull the screen outward. Remove the knife

access cover. Rotate the rotor so that the bolts

holding the chipper knife are accessible. Remove

the two bolts holding the knife and the knife itself.

Repeat for all 4 knives.

Grind the knife at 45 degrees.(See Figure A) The

knives can be ground on a bench grinder or by a

professional. Be careful when grinding so that the

knife material does not get too hot and change

color, this will remove the knife's special heat

treated properties. Use short grinding times and

cool with water. Try to remove an equal amount

off each knife to maintain balance. Replace the

chipper knives and tighten bolts to 20 foot

pounds. Replace the discharge screen.

ADJUSTING KNIFE CLEARANCE

The chipper knife should clear the chipping block

by 1/8 inch.(See Figure B) To adjust the knife

clearance, proceed as follows:

A. Remove the belt shield, discharge shield, and

the discharge screen. Remove the shaft cover

on the front side.

B. Loosen the two set screws holding the set collar

at the front rotor bearing. Loosen the set

screws holding the lock collars on the front and

rear rotor bearings.

C. Use a punch and hammer and tap the collars in

a direction opposite shaft rotation so they can

rotate freely.

D. Using a soft face mallet, tap the end of the rotor

shaft to obtain 1/8" clearance between the

chipper knife and the chipper block.(See

Figure B) Knife clearance can be checked at

the chipper inlet chute. Rotate the rotor and

check the clearance on all chipper knives.

E. When the clearance has been set, tighten the

eccentric lock collars on the bearings by

rotating them in the direction of shaft rotation.

Using a punch and hammer, “set” them with a

positive hammer tap. Tighten the lock collar set

screws. Slide the set collar against the front

bearing lock collar and tighten the two set

screws.

F. Check the double drive belts for proper

alignment. It may be necessary to move the

pulley on the rotor shaft an equal distance the

rotor was moved.

G. Make sure all set screws are tight and replace

discharge screen and all shields which were

removed.

Figure A

Figure B

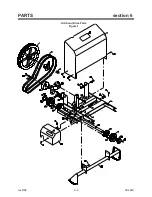

Summary of Contents for CS312

Page 16: ...rev 8 98 6 2 09 282C PARTS section 6 Hitch and Drive Parts Figure 1 ...

Page 18: ...rev 5 00 6 4 09 282C PARTS section 6 Frame Parts Figure 2 ...

Page 20: ...rev 8 98 6 6 09 282C PARTS section 6 Emergency Stop Switch Parts Figure 3 ...

Page 22: ...rev 5 00 6 8 09 282C PARTS section 6 MODEL CS313 Chipper Shredder Blower Parts Figure 4 ...

Page 30: ......