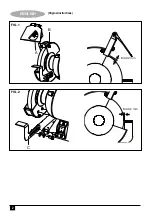

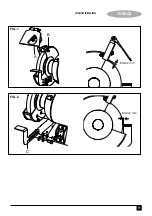

• The adjustment of the work rest shall be done gradually

so as to compensate the wear of the wheel, keeping the

distance between the work rest and the wheel as small

as possible, but in any case not greater than 2mm;

• Allow the tool to cool down after a continuous use of 20

minutes (S2 20min)

• Basic information on grinding wheels

1. Put grinding wheel in individual package, and keep in a

dry and well-ventilated place.

2. Various shortcomings during installation and operation

can lead to bursting of grinding wheels.

3. Ordinary grinding wheels are generally not designed to

withstand a greater lateral load.

4. Tap off cutting debris from the grinding wheel always

leads to damage of the grinding wheel.

5. Grinding wheels which may have an imbalance burst

easily.

6. An unbalance of a grinding wheel can not be completely

removed by withdrawing with a diamond dresser.

7. Incorrectly stored grinding wheels can burst immediately

after switching on, or individual small fragments fly away

like a bullet.

• Releasing jammed accessories. Release the pressure

on work piece, grinding wheels will return running.

• Lifting and transportation. Stop and disconnect machine.

Use two hands to lift up machine from two sides of

bottom of bearing housing.

• The work piece should be suitable for opening size

between wheels and plate. The machine is designed

and manufactured exclusively for grinding metals using

properly authorized grinding wheels. The grinding

machine must be used exclusively for this purpose.

Package Contents

The package contains:

1 Bench Grinder

2 Tool Rests

2 Eye Shields

2 Mounting Brackets

1 Instruction Manual

Features

This tool includes some or all of the following features.

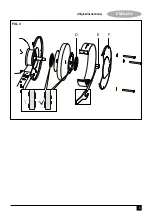

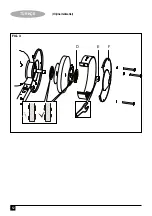

A. Spark Guard

B. Screw

C. Tool Rest

D. Flange

E. Clamping Nut

F. Protective Cover

6

ENGLISH

(Original instructions)

Read

I

nstructions

Manual

U

se Eye

Protection

U

se Ear

Protection

V ........ Volts

A ........ Amperes

H

z .......

H

ertz

W ........

W

atts

min ..... minutes

..... Alternating

Current

..... Direct

Current

n

0

....... No-Load

Speed

...... Class

II

Construction

.... Earthing

Terminal

.... Safety Alert

Symbol

.../min.. Revolutions

or Recipro-

cation per

minute

6. Labels on tool

The label on your tool may include the following symbols:

Position of date barcode

The Date Code, which also includes the year of

manufacture, is printed into the housing.

Example:

2014 XX JN

Year of manufacturing

Summary of Contents for STGB3715

Page 1: ...STGB3715 English Page 3 Turkish Page 11 ...

Page 2: ...ENGLISH 2 Original instructions FIG 1 FIG 2 C MAX 2 mm MAX 2 mm B A ...

Page 3: ...3 ENGLISH Original instructions FIG 3 D E F ...

Page 11: ...11 TÜRKÇE Orijinal talimatlar FIG 1 FIG 2 C MAX 2 mm MAX 2 mm B A ...