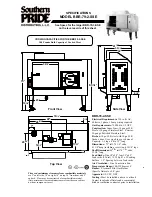

This appliance can only be installed in a room which

meets the ventilation regulations in force. But, in any

event the room must have a permanent vent of minimum

free air area, see below.

Detailed recommendations for air supply are given in the

Building Regulations and in BS 5440: Part 1. The

following notes are intended to give general guidance.

1.

Combustion and ventilation air supply to oil fired

appliance has to comply with the Building Regulations

and with BS 5410: Part 1. The air supply requirement

for oil fired appliance in 550mm

2

per kW of maximum

rated output above 5 kW. These requirements are

illustrated in OFTEC Technical Book No. 3.

2.

The combustion air supply to open flued appliances

should normally be provided at high level into a room

where it will not cause discomfort by creating a cold

draught across the floor.

3.

If combustion air is supplied through an under floor

duct the grilles at each end should be positioned in the

vertical plane to reduce the risk of blockage. Ducts

should be sized so as to reduce the resistance to air

flow.

4.

The ventilation requirement for kitchens in Part F of the

Building Regulations (England & Wales) is for

mechanical extract at the rate of 60 litres per second

or 30 litres per second if the fan is incorporated in a

cooker hood. The amount can be reduced if the

spillage of flue gases might be caused by the outflow

of air from the room.

Background ventilation is also required, either by

producing a constant extract rate of one air change per

hour or by having ventilation openings not less than

4000mm

2

.

5.

Extract fan should be positioned as far away from the

open flue as possible and should have a sufficient

dedicated air supply. To undertake a test the oil fired

appliance should be set in operation and the doors and

windows of the room containing it should be closed.

The extract fan should then be run at its maximum

setting. The oil fired heating appliance should be

observed to operate satisfactorily both before and after

the fan is switched on.

6. It is preferable for the air supply for an extract fan to be

located where it can serve the fan without the air

stream passing close to the oil fired appliance.

7.

Oil fired appliances must not draw the combustion air

from a garage.

Flow and return pipework between cooker diverter valves

must be 28mm diameter minimum.

Space and water heating systems should be in

accordance with the relevant recommendations of BS

5410: Part 1.

In a combined central heating and domestic hot water

system, the hot water storage vessel must be of the

indirect cylinder type to BS 1566: Part 1. The hot water

storage vessel should be insulated with not less than

75mm thick mineral fibre or its equivalent.

Cisterns and pipework should not be situated in areas

which may be exposed by freezing conditions should be

insulated.

Draining taps must be located in accessible positions

which permit the draining of the whole system, including

the heat storage vessel. Draining taps should be at least

1/2in BSP nominal size and be in accordance with BS

2879.

The appliance boiler section should be connected to a

cistern water supply, subject to a maximum head of

18.25m. The heating system must be designed (and

adjusted if necessary) to give temperature differential

across the boiler at full output of 10-14°C. When

horizontal runs are used the pipes should rise upwards in

the direction away from the appliance.

Circulating Pump

It is recommended that the selected pump be sized to suit

the boiler pressure loss and therefore adequate to give

the required temperature differential between the flow and

return.

The pump should be able to meet the requirements of the

system design and fitted in a readily accessible position.

Isolating Valves

Isolating valves (preferably of the keyless type) must be

fitted to the inlet and outlet of the circulating pump to

facilitate service and replacement of pump without

draining the system.

Inhibitor

A corrosion inhibitor

MUST

be added to the heating

system to protect the heat exchange and pipework.

Inhibitor must also be replaced if the system is drained

after installation. As a precaution the heating system

MUST

also be flushed out prior to the addition of the

inhibitor to ensure any flux, debris is removed.

10

Site requirements

AIR SUPPLY

120K

250cm

2

150K

290cm

2

MODEL

MIN. AIR REQUIREMENT

WATER CIRCULATION SYSTEM

Summary of Contents for Alpha 120K

Page 13: ...13 Site requirements FIG 6 External wiring with 2 zone valves ...

Page 14: ...Site requirements 14 FIG 7 ...

Page 22: ...22 FIG 16 ...

Page 23: ...23 ...