17

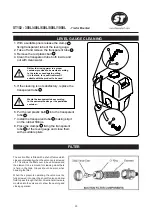

END OF TREATMENT - STORAGE

DAILY

The operator must:

If the machine is equipped with unit-washing tank:

a. Carry out the hydraulic circuit washing process spraying on a piece of ground

treated yet.

Attention:

The sprayer to be sprayed around 5 sec..

b. Wash the inside of the tank:

1. Disengage the fan.

2. Open the cock and position the lever.

3. Engage the drive outlet (PTO).

Engage the PTO with the engine of the tractor at low speed and with maximum modulari-

ty, obtaining soft and progressive graft and avoiding abrupt starts of the cardan shaft.

6. Open the tap and place the hose into the top opening.

7. Rinse the tank until the water in the spray-line rinsing tank is totally run out, if needed wash the

internal of the tank with a jet of clean water as expected for the machine without circuit-washer.

8. Disengage the drive outlet (PTO).

9. Discharge the rinsing water in area with a drain basin and arrange the waste following the

country rules.

10. Spray the rinsing water in the previously treated area. Discharge the remaining water of the

tank and pipes (about 5 to 6L balance in tank), gathering it in a proper waste container following

the country rules or use it again, putting in the tank, for a next treatment if this will be suitable

with the product to use.

The machine must be stored in a secure or closed place, so as to prevent access to

unauthorized personnel.

ST102 - 300L/400L/600L/800L/1000L

- Tractor Mounted