1B3-138 OM600 ENGINE MECHANICAL

6. Check the timing.

New

After approx. 20,000km

ATDC 11.33°

ATDC 12°

Notice

If timing is out standard, the camshaft should be checked

for wear and the timing chain for stretch. If a difference of

more than 4° exists, the timing chain should be replaced.

7. Replace the gasket and install the cylinder head cover.

Tightening Torque

10 Nm

Measurement Procedure

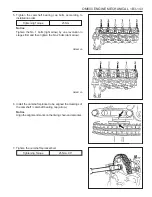

1. Remove the cylinder head cover.

2. Rotate the engine in the direction of engine rotation until

the intake valve of NO. 1 cylinder is completely closed. The

cam lobe faces up (arrow).

Notice

Do not rotate the engine at the bolt of the crankshaft

sprocket. Do not rotate the engine in the opposite direction

of engine rotation. If do, this will cause serious measuring

errors.

3. Install the dial gauge holder and dial gauge (7) with the

extension (8) to the cylinder head and position the tracer

pin (9) onto the valve tappet (intake valve of cylinder NO.1)

with a preload of min. 3mm.

Notice

The tracer pin should be positioned exactly vertical.

Dial gauge Holder 363 589 02 21 00

Dial Gauge 001 589 53 21 00

Extension 366 589 00 21 05

4. Set the dial gauge to ‘0’.

5. Rotate the engine further in direction of rotation until the

dial gauge has moved back by 2mm (valve lift) to 1mm.

Tools Required

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge Holder

366 589 00 21 05 Extension

Summary of Contents for OM600

Page 12: ...1B3 12 OM600 ENGINE MECHANICAL MAINTENANCE AND REPAIR ON VEHICLE SERVICE ENGINE ASSEMBLY ...

Page 51: ...OM600 ENGINE MECHANICAL 1B3 51 49 Remove the cylinder head 2 and gasket 3 OM661LA ...

Page 145: ...OM600 ENGINE MECHANICAL 1B3 145 CHAIN TENSIONER 1 Chain Tensioner 80Nm 2 Seal Replace ...

Page 171: ...1B3 172 OM600ENGINE MECHANICAL Oil Circulation ...

Page 172: ...OM600 ENGINE MECHANICAL 1B3 173 Oil Filter a From Oil Pump b To Main Oil Gallery c To Oil Pan ...