OM600 ENGINE MECHANICAL 1B3-33

6. Measure the ‘X’ by using a vernier caliper.

7. Mount the turning tool onto the countersink tool and rotate

to the right approx. 5 revolutions by applying slight pressure.

1. Remove the injection nozzle.

2. Remove the prechamber.

3. Cover the prechamber bore to avoid any chips dropping

into the combustion chamber.

4. Remove the protective sleeve from the countersink and

rotate the countersink into the prechamber bore to be

machined as far as the stop.

Counter Sink 601 589 00 66 00

5. Maintain size ‘X’ from the top edge of mandrel to the top

edge of the sleeve with the gauge.

Height Gauge 667 589 00 23 00

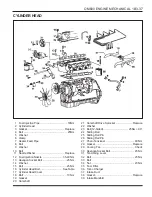

Summary of Contents for OM600

Page 12: ...1B3 12 OM600 ENGINE MECHANICAL MAINTENANCE AND REPAIR ON VEHICLE SERVICE ENGINE ASSEMBLY ...

Page 51: ...OM600 ENGINE MECHANICAL 1B3 51 49 Remove the cylinder head 2 and gasket 3 OM661LA ...

Page 145: ...OM600 ENGINE MECHANICAL 1B3 145 CHAIN TENSIONER 1 Chain Tensioner 80Nm 2 Seal Replace ...

Page 171: ...1B3 172 OM600ENGINE MECHANICAL Oil Circulation ...

Page 172: ...OM600 ENGINE MECHANICAL 1B3 173 Oil Filter a From Oil Pump b To Main Oil Gallery c To Oil Pan ...