19

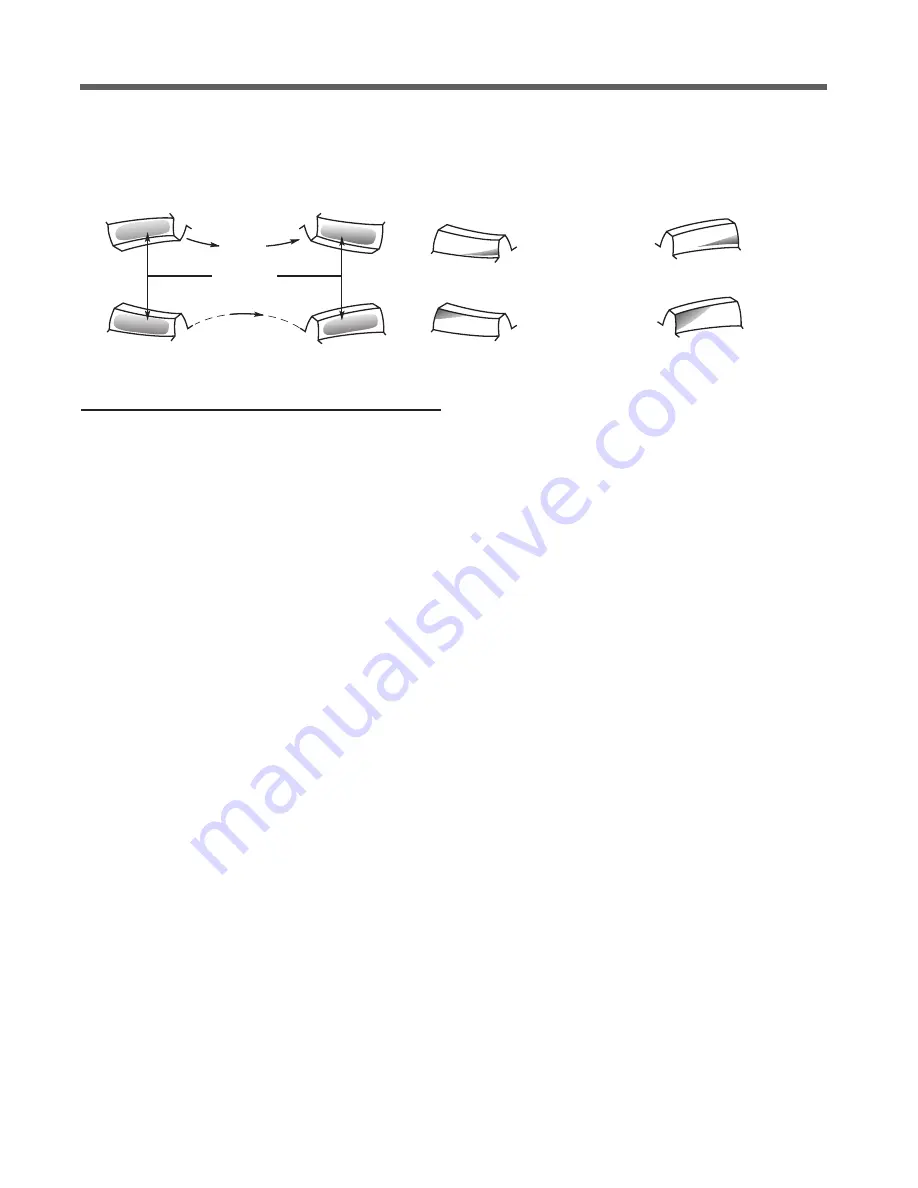

DIRECTION OF ROTATION

RING GEAR

ORIGINAL

PATTERN

AFTER

BREAK IN

*

*

*

*

CONVEX SIDE

ENTERING

CONCAVE SIDE

LEAVING

CONCAVE SIDE

CONVEX SIDE

OUT OF POSITION CONTACT

CAUSE: PINION TOO CLOSE TO

GEAR CENTER.

REMEDY: MOVE PINION OUT.

OUT OF POSITION CONTACT

CAUSE: PINION TOO FAR FROM

GEAR CENTER.

REMEDY: MOVE PINION IN.

CORRECT PINION AND RING GEAR TOOTH CONTACT PATTERNS

INCORRECT RING GEAR TOOTH CONTACT PATTERNS

Figure 17

Spiral Bevel Gear Tooth Pattern

field repair

The tooth contact pattern should again be checked to determine

if adjusting the backlash has produced any shift. If it has shifted,

move the pinion in the opposite direction the gear was moved

with respect to the cone center. If the gear mounting distance

is reduced, increase pinion setting distance, and vice versa, an

amount proportional to the number of teeth in the respective

members. For example: on a 10 to 1 gear set, if the ring gear

was moved .010" (.25mm) , the pinion should be moved 0.001"

(.025mm). This would be necessary only if the contact pattern

had visually shifted due to movement of the ring gear while

adjusting backlash.

When setting a used set of gears, follow the method outlined

above. However, depending upon the amount of wear, it may be

necessary to set the gears up with slightly greater backlash in

order to obtain proper contact. Proper tooth contact pattern

is the most important factor for correct installation.

Should a condition be encountered where correct contact cannot

be obtained as described in this manual, the Geareducer should be

returned to Marley in exchange for a factory reconditioned unit.

Installation and Lubrication

Refer to the Operation and Maintenance Instructions at the

beginning of this manual.