IM-P157-38

CMGT Issue 4

20

Steam/Water Mixing Stations (MkII valves - 2002 onwards) Safety and Operation

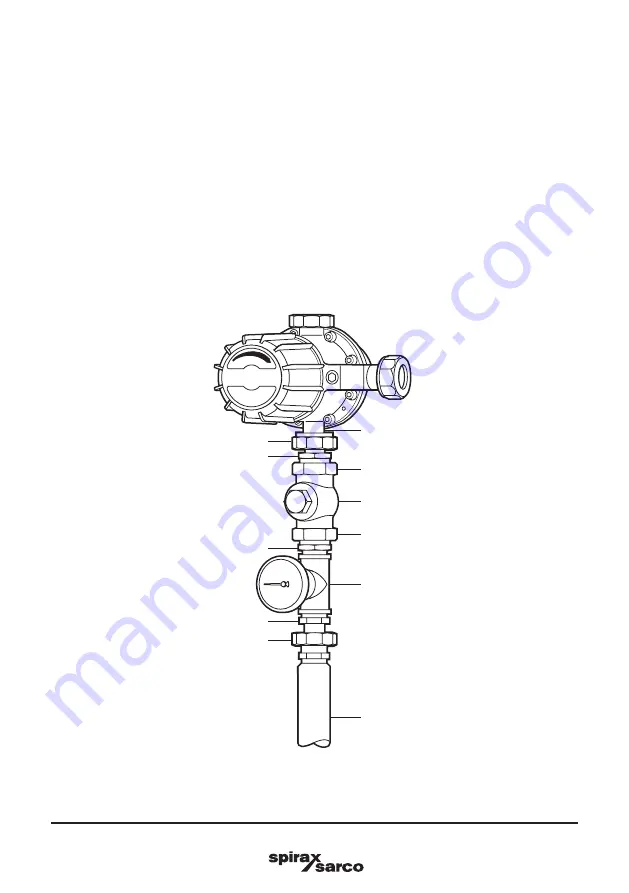

Fig. 6

INLET

OUTLET

'T' piece

Steam/water mixing valve

Reducing nipple

1" x

¾

" reducing nipple

Equal nipple

Union

TCO1

Hose (with protective sleeve)

Union

Hot water outlet

½

" and

¾

" station only

NOTE: For satisfactory hosedown purposes steam and water supplies should have a minimum

pressure of 3 bar g (43.5 psi g) and a maximum pressure of 10 bar g (145 psi g) and are required

to be nominally equal. (Please see Section 7 , 'Fault finding', for details). The minimum pressure

provides a reasonable spray velocity and flowrate at the gun (see Figure 7).

When replacing a steam/water mixing valve in a mixing valve station the spool pieces supplied must be

installed between the pressure gauge 'T' piece and the mixing valve union in the steam and cold water supply

lines. This will take account of the smaller overall dimension of the replacement valve.

Connect the pipework fittings according to Figure 4 using a suitable thread sealing medium. The TCO1 is

installed between the hot water outlet of the mixing valve and the equal 'T' that houses the thermometer. The

TCO1 is connected to the equal 'T' using a 1" x

¾

" reducing nipple. The other end is connected to the valve via

a reducing nipple and the male/female union joint on the mixing valve. Care should be taken to ensure that the

hexagon cap is in line with the dial face of the thermometer when the arrangement is tightened into the valve.

To attach the hose to the thermometer 'T' piece first screw the male/male equal nipple into the 'T' piece.

The hose is then connected to the male/male equal nipple via the female union on the hose (see Figure 6).