eLift operating instructions

- eLift equipped tables only

Control

button

Reset Procedure:

1. Press and hold the “Down” button. The worksurface will lower to the

lowest position and stop moving.

2. Release the “Down” button.

3. Press and hold the “Down” button again. The worksurface will lower

slightly and the leg mechanisms will reset.

Down

CAUTION

Always unplug the eLift before working under the worksurface.

Although this table utilizes an anti-collision feature that briefly stops

and reverses the motion of the table in the event of an obstruction,

use caution when raising or lowering the worksurface.

Do not

sit at,

under, or on the worksurface when operating the lift mechanism and

be sure the table movement does not interfere with objects or people.

Use caution when raising or lowering the worksurface

!

Up

CAUTION

Keep clear of pinch points during worksurface movement. Note:

The lift actuators are rated at a maximum capacity of 180 lbs each.

CAUTION

USE CAUTION WHEN RAISING OR LOWERING TABLE!

curved or

rectangular end

worksurface

control

button

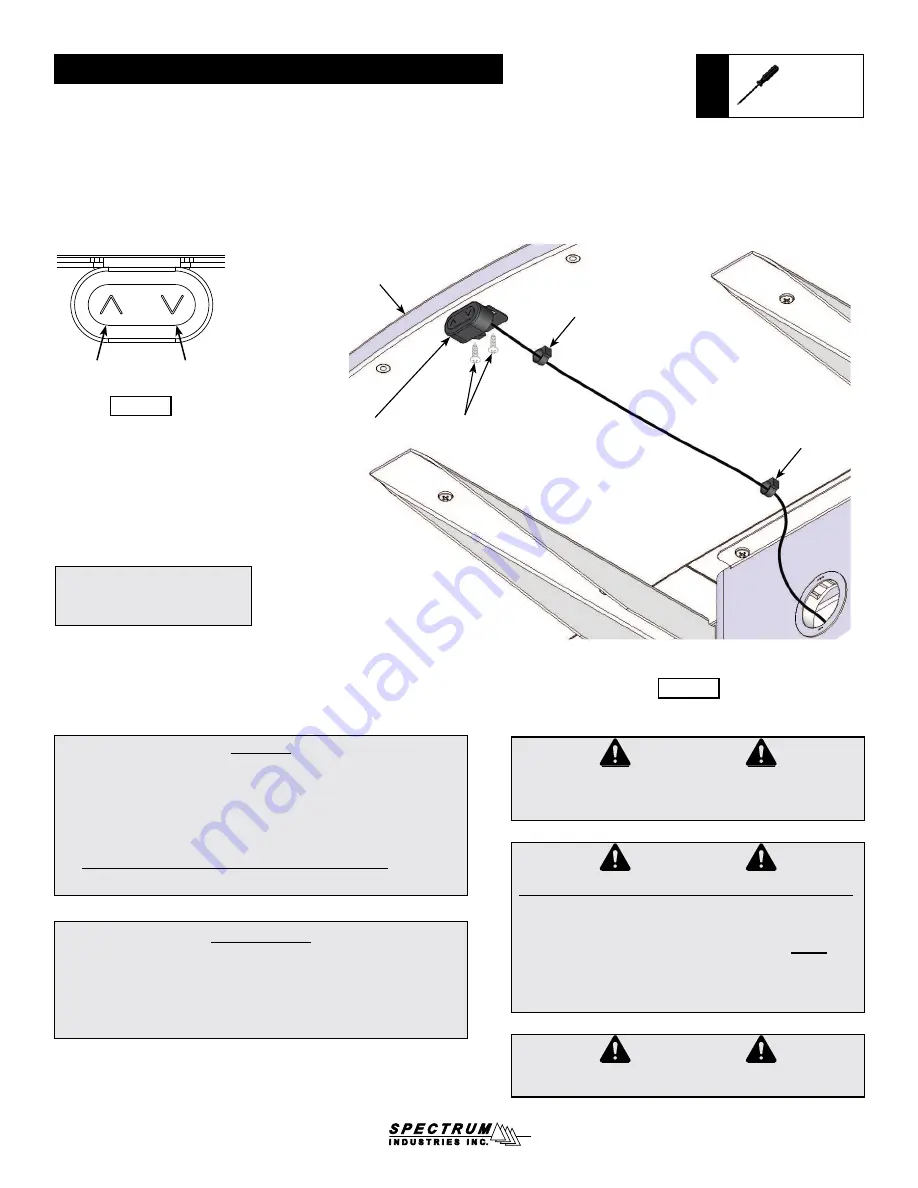

1. Attach the control button bracket under the end worksurface with (2) #8 x 5/8”

PHSM screws and pre-drilled pilot holes in the center of the end worksurface.

2. Push the control button onto the bracket.

3. Use the included pine tree clips to secure the cord to the worksurface.

0115700R2 Page 9 of 17

Phillips

screwdriver

Tools

Required

Operation:

1. Plug the 11-foot, 15-amp power cord into a wall outlet.

2. Locate the “Up” and “Down” buttons on the control pad.

3. To raise or lower the worksurface, press and hold the “up” or “down”

arrow keys on the control pad until the worksurface reaches the desired

height. The worksurface maximum height is 42”, minimum height is 29”.

Keep clear of pinch points during worksurface movement.

#8 x 5/8” PHSM

screws

Pine tree clip

pine tree clip

Figure 10

Figure 9

Note: The control button can also

be mounted under one of the side

worksurfaces if necessary.