P

The Leader in Nitrogen Generation Technology

FPS-900-RS O&M Manual

Version: 3; 3/2020

Page 19 of 28

a) Once it reaches 65-

70 PSIG, the system will enter “Standby” mode and automatically shut

off the internal air compressor. Check the controller on the control panel for the

“

STANDBY

” display.

b) Once in standby, note the pressure reading on the tank pressure gauge. Monitor the

pressure for the next 5 minutes for any loss in pressure. If there is a pressure drop, check

for leaks around connection fittings, otherwise proceed to the next step.

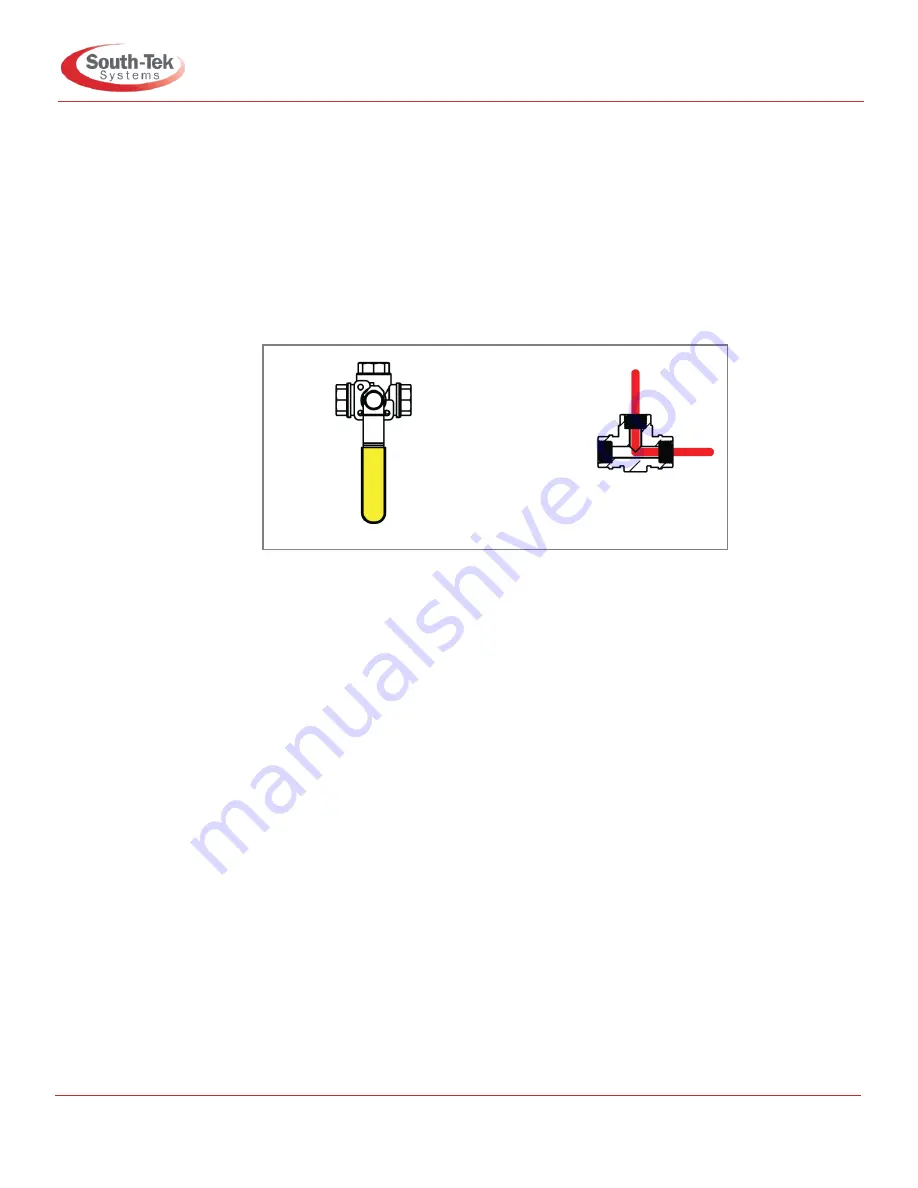

7. Switch the 3-

way ball valve on the system output to the “Nitrogen Out” position and the system

will fill with nitrogen.

Figure 4: 3-way valve in N

2

out position

8. Completely fill the storage tank and then allow the nitrogen generator to go into standby mode

again.

9. Once in standby mode, monitor the tank pressure gauge for 5 minutes to ensure that no significant

leaks are in the sprinkler system.

8.2. Checking for Leaks

The BlastOff

®

provides early warning alarms for potential leakage. With a suspected leak, first

listen for leaks and then spray soapy water around the connections. When a leak occurs, isolate

the area and relieve pressure before working on it. Fix the leaking part and return the system back

to operation. If no leak is heard (or no bubbles are seen), turn off the unit and try isolating sections

to see if there’s a pressure loss. Consult with your installer if you cannot find the leakage area.

8.2.1. To determine if the leak is between the Generator and the Nitrogen Tank:

1. With the unit powered on, close off both ball valves on the nitrogen tank. Note the storage tank

pressure.

2. Allow the system to continue running. Within 10 minutes or less, the system should reach the

“Standby” mode.

3.

Wait 5 minutes and if the system remains in “standby” mode, then the leak is after the nitrogen

generator. Read the nitrogen tank pressure and if the pressure has changed, the leak is within