-18-

For Machines Mfg. Since 7/09

EVS Toolroom Lathes

P R E P A R A T I O N

9.

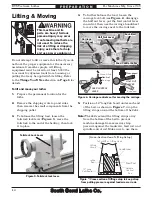

Move the feed direction forward/reverse lever

to the middle (neutral) position, as shown in

Figure 20

.

Figure 20. Feed direction forward/reverse lever in the

neutral position.

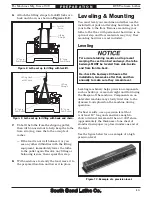

10.

Disengage the half nut lever, put the feed

control lever in neutral, and make sure the

carriage lock bolt is loose (see

Figure 6

).

This step will allow the carriage to move

freely when the handwheel is rotated and

make sure that the carriage will not move

when the lathe is started.

F

ORWARD

R

EVERSE

N

EUTRAL

Figure 17. Control panel-test run.

Stop Button

Pump Switch

6.

Turn the spindle speed dial (

Figure 18

) all

the way counterclockwise (lowest speed) to

avoid possibility of a high-speed start.

Figure 19. Gearbox range lever in middle position.

L

OW

N

eutral

H

IGH

Figure 18. Spindle speed controls.

Low

20-400 RPM

High

400-2500 RPM

Spindle Speed Dial

7.

Move the spindle speed range lever (

Figure

18

) to the left so the headstock is set in the

low range (20-400 RPM). (You may need to

slightly rotate the chuck by hand to engage

the lever.)

8.

Move the gearbox range lever to the middle

(neutral) position, as shown in

Figure 19

.

Figure 21. Controls used to disengage carriage so that

it will move freely when the handwheel is turned.

Engaged

HALF NUT

LEVER

Disengaged

Cross Slide

Neutral

FEED CONTROL

LEVER

Carriage

Feed Control Lever

Half Nut Lever

Carriage Lock Bolt