For Machines Mfg. Since 8/11

Model SB1001 8K

™

Lathe

-35-

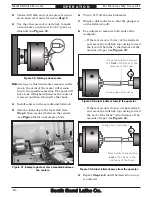

O P E R A T I O N

Mounting Workpiece Between

Centers

1.

DISCONNECT LATHE FROM POWER!

2.

Center drill both ends of the workpiece.

3.

Install the MT#3 dead center in the spindle

with a lathe dog and faceplate, then install

the MT#2 dead center in the tailstock.

4.

Generously lubricate the workpiece center

holes, then mount the workpiece on the

centers and hold it in place with light

pressure from the tailstock center.

5.

Seat the center firmly into the quill by

rotating the tailstock handwheel clockwise

to apply pressure against the workpiece (see

the example photo in Figure 38).

Note:

Only apply enough pressure with

the tailstock quill to securely mount

the workpiece between centers. Avoid

overtightening the center against the

workpiece, or the center may become difficult

to remove later, and the excess pressure

will result in unnecessary friction and heat,

which may damage the workpiece and

center.

Figure 38. Example photo of a workpiece mounted

between the centers.

Carriage & Slide Locks

The carriage, cross slide, and compound rest

can be locked into position to provide additional

rigidity during operation, especially during heavy

cuts.

To lock the carriage, use a 5mm hex wrench to

tighten the carriage lock cap screw shown in

Figure 39.

To lock the cross slide or compound rest, use an

8mm wrench to loosen the hex nuts and a 2.5mm

hex wrench to fully tighten the two end gib

adjustment set screws on both sides.

Note: When it is no longer necessary to lock

these components, make sure to loosen/re-adjust

the lock fasteners to allow the components to

freely move (see Figures 39–40).

Figure 40. Location of compound rest gib screws.

Compound Rest

Gib Screws

Figure 39. Location of carriage lock and cross slide

gib screws.

Carriage

Lock

Cross Slide

Gib Screws