For Machines Mfg. Since 8/11

Model SB1001 8K

™

Lathe

-33-

O P E R A T I O N

Live Centers

A live center (see Figure 35 for an example)

has bearings that allow the center tip and the

workpiece to rotate together—it can be installed

in the tailstock quill for higher speeds. However,

a live center typically does not provide the

same level of rigidity as a dead center, and final

workpiece accuracy can suffer as a result.

Centers

Figure 34 shows the MT#3 and MT#2 dead

centers included with the lathe. In addition, an

MT#3–MT#2 tapered spindle sleeve is included

for mounting the MT#3 center in the spindle.

Figure 34. Tapered spindle sleeve and dead centers.

Adapter

Sleeve

MT#3

Center

MT#2

Center

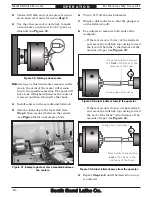

Figure 35. Example of a live center (SB1241 MT#2

Live Center shown).

Dead Centers

A dead center is a one-piece center that does not

rotate with the workpiece and is used to support

long, slender workpieces

Use the dead center in the spindle for operations

where the workpiece rotates with the center and

does not generate friction.

When the dead center is used in the tailstock,

the workpiece pivots on the tip of the center. The

tip must be generously lubricated during the

operation to avoid premature wear and maximize

smooth operation. Using low spindle speeds will

also reduce the heat and wear from friction.