-66-

For Machines Mfd. Since 7/21

South Bend Tools

Model SB1123

S E R V I C E

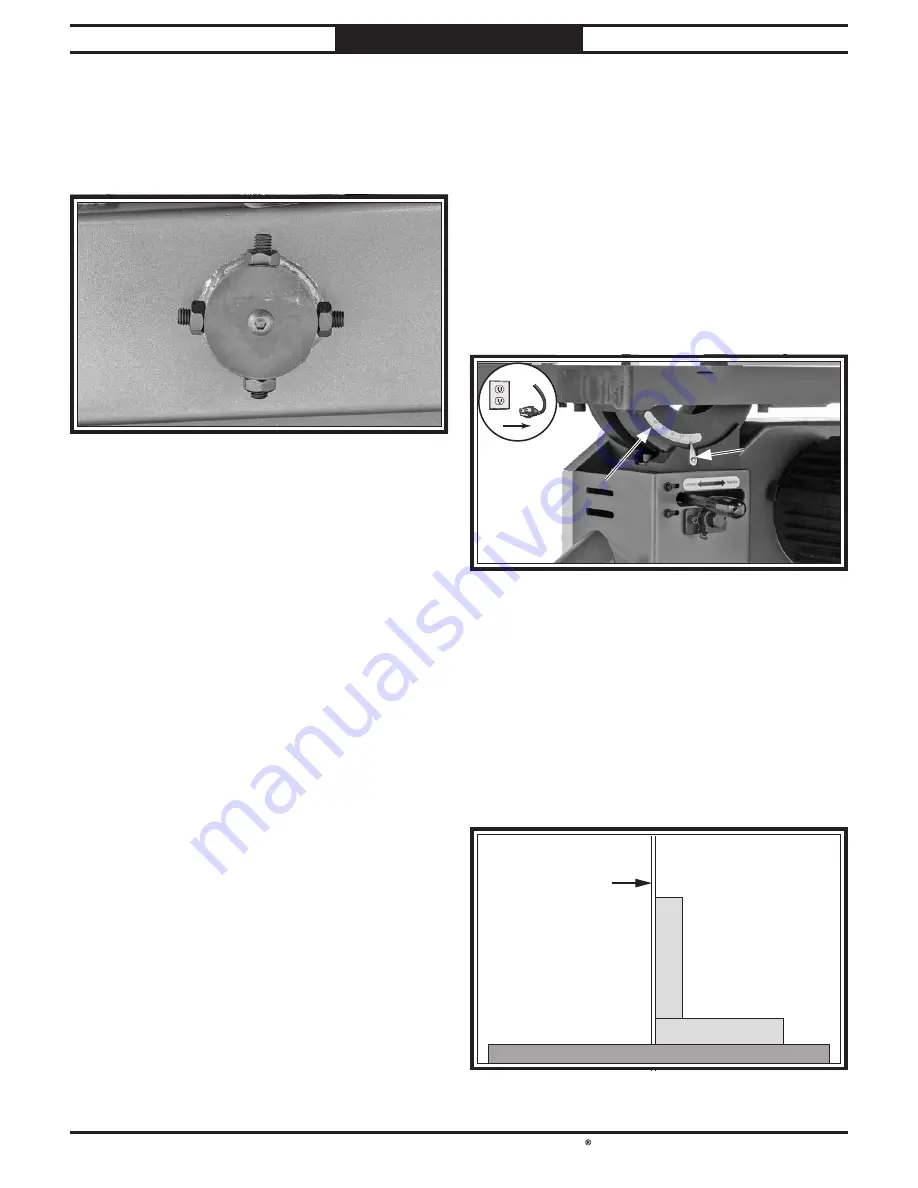

To adjust lower wheel shaft position:

1.

DISCONNECT MACHINE FROM POWER!

2.

Loosen jam nuts on lower wheel adjustment

hub (see Figure

108).

3.

Loosen one tilt adjustment set screw, then

tighten opposing set screw approximately an

equal amount.

4.

Check wheels with coplanarity gauge, and

repeat Step 3 as needed until lower wheel is

parallel and coplanar with upper wheel.

5.

Tighten jam nuts to lock tilt adjustment set

screws in position.

6.

Perform previous Checking Wheel

Alignment procedure, beginning on Page

63, and adjust wheels as necessary to make

them parallel and coplanar.

7.

When wheels are parallel and coplanar,

remove blade, re-install table, and then re-

install blade.

Calibrating Table Tilt

Scale Pointer

The table tilt scale pointer (see Figure

109

)

was calibrated at the factory. However, after

prolonged use the pointer may shift, requiring

adjustment.

Note:

The table tilt scale functions as a basic

guide only. For high-precision cuts, use a

protractor or bevel gauge to set the angle of table

tilt.

To calibrate table tilt scale pointer:

1.

DISCONNECT MACHINE FROM POWER!

2.

Place one edge of square on table and other

edge of square against blade side, as shown

in Figure 110.

Blade

Table

Square

Figure 110. Adjusting table perpendicular to blade

Adjusting table perpendicular to blade

(side to side).

(side to side).

Tools Needed

Qty

Machinist's Square ................................................1

Phillips Head Screwdriver #2 ...............................1

Figure 108. Lower wheel adjustment controls.

Lower wheel adjustment controls.

Side

Side

Tilt

Tilt

Bottom Tilt

Bottom Tilt

Side

Side

Tilt

Tilt

Adjustment

Adjustment

Hub

Hub

Top Tilt

Top Tilt

Figure 109. Location of table tilt scale and pointer.

Location of table tilt scale and pointer.

Table Tilt

Table Tilt

Scale

Scale

Pointer

Pointer

!