Installation

DocNr.: 03-4655 R03.01 | 22.09.2015 | en-US | Ultrasonic Generator

25

Connecting irrigation

Danger of crushing

Rotating parts in the open irrigation pump may cause injury to fingers when the irri-

gation tubing is being inserted.

Do not reach inside the irrigation pump.

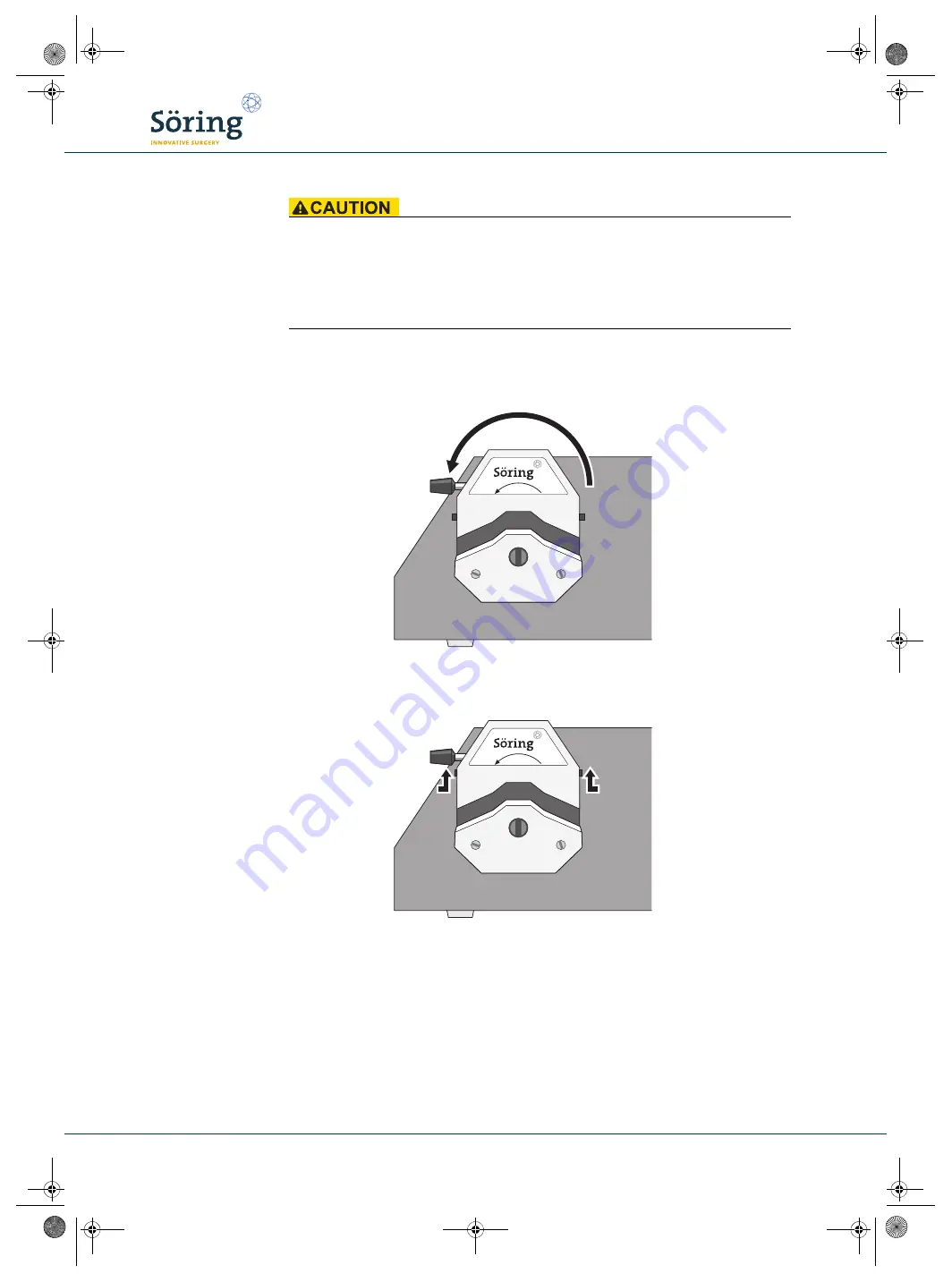

5. Open the irrigation pump.

To do this, push the lever to the left.

6. Move both locking clamps into the upper position.

To do this, press on the locking clamps and slide them up.

out.fm Seite 25 Dienstag, 22. September 2015 3:24 15