1-17 (E)

VPL-FHZ65

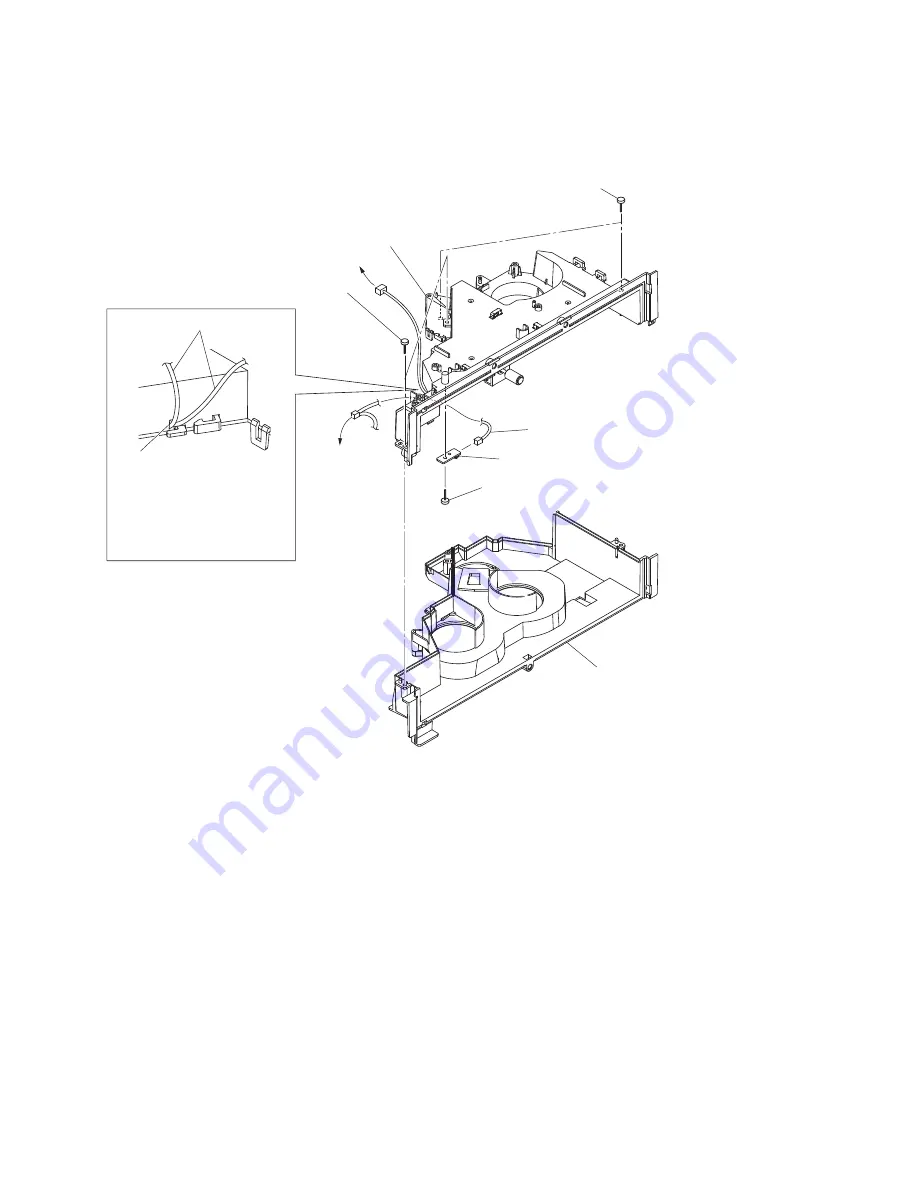

1-6-8. TA Board

5

Harness

1

Two screws

(BVTP3

)

12)

2

Two screws

(BVTP3

)

12)

7

TA board

6

Screw

(BVTP3

)

12)

4

Case (FILTER BOTTOM)

3

Case (FILTER TOP)

$

Assemble the case (FILTER TOP)

and case (FILTER BOTTOM) by

passing the harnesses through

the groove portion.

Groove portion

Harnesses

To the C board

To the C board

Summary of Contents for VPL-F430HZ

Page 8: ......

Page 56: ...1 48 E VPL FHZ65 6 Change the password of Administrator ...

Page 96: ......

Page 109: ...3 13 VPL FHZ65 Optional Lens VPLL Z3024 VPLL Z3009 VPLL Z3032 VPLL 3077 ...

Page 114: ......

Page 115: ......