5-27

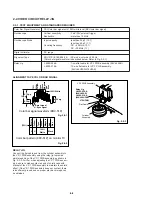

4-3-3. GUIDE ROLLER HEIGHT ADJUSTMENT

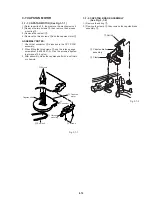

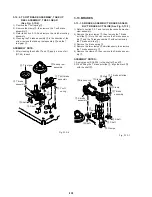

(See Figs. 4-3-3 and 4-3-4)

1) Play the Alignment Tape (NTSC: KRV-52NE, PAL: KRV-

52PL) and check that the envelope waveform is at its

maximum at the tracking centre. Then, after loosening

the S guide roller and the T guide roller by rotating them

anticlockwise, tighten them in turn until the envelope

waveform becomes flat. If the envelope waveform is not

at its maximum at the tracking centre, refer to section 4-

3-4 and carry out a rough adjustment of the horizontal

position of the audio R/P head (ACE head) before

adjusting the guide rollers.

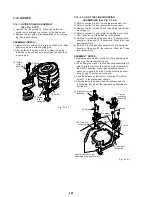

2) Adjust the S guide roller.

1

Press the tracking button (Channel – ), and check

whether, when the envelope waveform has reached

50% of its maximum, the front half of the envelope

waveform is flat. If not, fine-tune the S guide roller as

follows.

a. If the front half of the envelope waveform is as shown

in Fig. 4-3-4 (a), this means that you have pressed the

S guide roller too far. Therefore, loosen it slightly, and

when it is in the state shown in Fig. 4-3-4 (b), tighten it

again, stopping when the envelope waveform is flat.

b. If the front half of the envelope waveform is as shown

in Fig. 4-3-4 (b), this means you have not pressed the

S guide roller far enough. Therefore, tighten it slightly,

stopping when the envelope waveform becomes flat.

c. If the front half of the envelope waveform is as shown

in Fig. 4-3-4 (c), it may happen that when you tighten

the S guide roller, the wrapper waveform does not

disappear, but sinks into the flat part, as shown in Fig.

4-3-4 (d). If this happens, the status shown in Fig. 4-3-

4 (c) is normal, so loosen the S guide roller, then

tighten it again until the envelope waveform is as

shown in Fig. 4-3-4 (c).

2

Check that at the tracking centre, the output of the

front half of the envelope waveform is not less than

80% of the maximum.

3

Rotate the S guide roller 20

°

anticlockwise.

3) AdjusttheTguide roller.

1

press the tracking button (channel – ) and check

whether, when the envelope waveform is 50% of

maximum, the back half of the envelope waveform is

flat. If not, loosen the T guide roller slightly, then

tighten it gradually until the back half of the envelope

waveform becomes flat.

2

Check that the output for the back half of the envelope

waveform is at its maximum at the tracking centre.

4) Check that the envelope waveform does not fluctuate

when you switch from F-SEARCH to PLAY or from R-

SEARCH to PLAY. If it does fluctuate, repeat steps 3)

and 4).

Normal

Pressed

too far

Not pressed

far enough

Eccentric screwdriver

(J-6082-044-A)

S guide roller

T guide roller

Do not touch

the fixed

screw

The tape should not pass along

the cylinder lead surface

Fig. 4-3-3

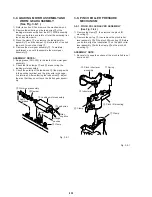

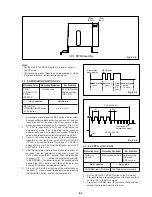

If the envelope waveform

is at maximum at the

tracking centre, adjust to

flat.

In normal status, the waveform

will be flat even when the

envelope waveform is reduced

to 50%.

100%

50%

50%

50%

50%

50%

(a) S guide roller

pressed too far

(d) S guide roller

pressed too far

(b) S guide roller not

pressed far enough

(c) Normal status for

wrapper waveform

Fig. 4-3-4

Summary of Contents for SLV-L45AR

Page 6: ...1 2 ...

Page 7: ...1 3 ...

Page 8: ...1 4 ...

Page 9: ...1 5 ...

Page 10: ...1 6 ...

Page 11: ...1 7 ...

Page 12: ...1 8 E ...

Page 17: ...3 2 MECHANISM CONNECTION DIAGRAM ...

Page 18: ...3 3 3 4 SLV L45AR L65HFAR L75HFAR OVERALL WIRING DIAGRAM SLV L45AR ...

Page 19: ...SLV L45AR L65HFAR L75HFAR OVERALL WIRING DIAGRAM SLV L65HFAR L75HFAR 3 5 3 6 ...

Page 20: ...3 7 3 8 SLV L45AR L65HFAR L75HFAR SYSTEM CONTROL SERVO CIRCUIT DIAGRAM SLV L45AR ...

Page 21: ...3 9 3 10 SLV L45AR L65HFAR L75HFAR SYSTEM CONTROL SERVO CIRCUIT DIAGRAM SLV L65HFAR L75HFAR ...

Page 25: ...SLV L45AR L65HFAR L75HFAR 4 3 4 4 CP 1 BOARD VA A VIDEO AUDIO TUNER CIRCUIT DIAGRAM SLV L45AR ...

Page 33: ...4 19 4 20 CP 1 BOARD SY A SYSTEM CONTROL SERVO CIRCUIT DIAGRAM SLV L65HFAR L75HFAR ...