© Trynex International 2009 L1102

5 — 32

Operating the Spreader

PREPARATION

CAUTION –

Sweep area clear of foreign objects or obstacles that could cause personal injury. Keep other persons, children, or

animals out of the area to be spread.

SPREADER LOADING

WARNING –

Do not overload vehicle. Use chart below to calculate weight of material. Weights of material are an average for

dry materials.

Material

Weight Per Cubic Ft.

Rock Salt

35-40 lbs.

Sand/Salt Mix

95-120 lbs.

•

Be sure to comply with manufacturer’s maximum gross vehicle weight ratings.

•

Warning

– Never leave materials in hopper for long periods of time as salt is hygroscopic and will attract atmospheric

moisture and harden up. When spreading sand mix, a 1:1 ratio for Sand/Salt mix is recommended to prevent the

material from freezing.

SPREADING TIPS

•

Never exceed 10 m.p.h. when spreading.

•

For a wider pass, increase spinner speed.

•

For a heavier pass, drive slower, or increase auger speed.

•

Never operate spreader near pedestrians.

•

Spread ice melters with the storm to prevent unmanageable levels of ice.

•

Calculate spread pattern when near vegetation.

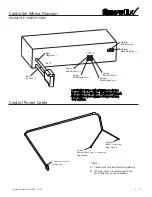

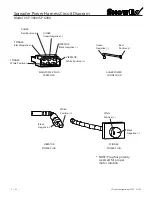

SP-3000/SP-6000 CONTROL OPERATION

•

The Dual Variable Speed Control has dual finger-tip dials for maximum performance, digital system status with warning

protection and built-in Vibrator Switch.

•

To start, press power switch on controller and spreader will accelerate to speed set on spinner and auger dials.

•

To stop, press power switch on controller to off position.

•

Speed of auger and spinner may be adjusted separately to get desired flow and spread distance

from spreader.

•

The Vibrator Switch is needed for dense material or to increase the flow to the auger. This eliminates bridging of material

in hopper.

Model # SP-3000/SP-6000

Summary of Contents for Vee Pro 3000

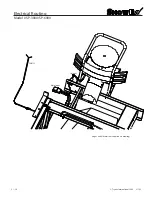

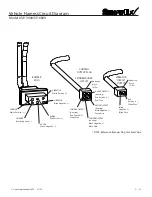

Page 8: ...Trynex International 2009 L1102 5 8 Side and Bottom View Model SP 3000...

Page 9: ...Trynex International 2009 L1102 5 9 Side and Bottom View Model SP 6000...

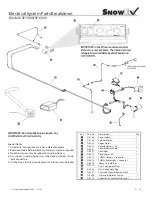

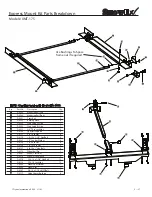

Page 11: ...Trynex International 2009 L1102 5 11 Main Assembly Parts Breakdown Model SP 3000...

Page 13: ...Trynex International 2009 L1102 5 13 Main Assembly Parts Breakdown Model SP 6000...

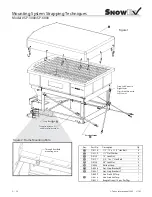

Page 18: ...Trynex International 2009 L1102 5 18 Assembly View Model SP 3000 SP 6000...

Page 39: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 39...

Page 40: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 40...

Page 41: ...THIS PAGE INTENTIONALLY LEFT BLANK Trynex International 2009 L1102 5 41...