21

Section 4 - ADJUSTMENTS & REPAIR

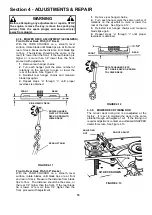

4.5.5. BATTERY

TESTING

There are two types of battery tests: Unloaded and

Loaded. The unloaded test is the procedure that will

be discussed. It’s the simplest and most commonly

used. An unloaded test is made on a battery without

discharging current. To perform unloaded testing,

check charge condition using either a hydrometer or

voltmeter.

1. Using a voltmeter, voltage readings appear

instantly to show the state of charge. Remember to

hook the positive lead to the battery’s positive

terminal, and the negative lead to the negative

terminal.

2. A hydrometer measures the specific gravity of

each cell. The specific gravity tells the degree of

charge; generally, a specific gravity of about 1.265

to 1.280 indicates full charge. A reading of 1.230 to

1.260 indicates the battery should be charged. The

chart on the next page shows the charge level as

measured by syringe float hydrometer, digital

voltmeter and five ball hydrometer.

4.5.6. NEW BATTERY PREPARATION

1. Remove battery from carton.

2. Place battery in a well ventilated area on a level

non-concrete surface.

3. Remove battery cell caps. Fill cells as required

with electrolyte (purchased separately) to proper

level. Fill to 3/16” above cell plates. Filling battery

with electrolyte will bring the battery to 80% charged

state.

4. With cell caps removed, connect battery charger to

battery terminals; RED to positive (+) and BLACK to

negative (-) terminal.

WARNING

DO NOT OVERFILL! Never attempt to charge battery

while installed on the Yard Cruiser. Never use

“BOOST” chargers on the battery.

IMPORTANT: 3/16” above cell plates is the recommended

level. However do not try to measure this dimension. Never

place anything in battery other than specified electrolyte.

5. Slow charge the battery at 1 amp for 2 hours to

bring the battery to full charge.

6. After charging, check level of electrolyte and add

as needed to bring level to 3/16” above cell plates.

7. Reinstall cell caps.

8. Install battery into power unit. Connect over flow

tube.

9. Connect positive (+) cable (red) first, from wiring

harness to the positive terminal (+) on battery using

bolt and nut provided in hardware bag. Connect

negative (-) cable (black) last, to negative terminal

(-) on battery using bolt and nut. Apply a small

amount of grease over terminals to prevent

corrosion.

WARNING

Shield the positive terminal with terminal cover

located on battery harness. This prevents metal from

touching the positive terminal which could cause

sparks.

4.5.7. BATTERY TESTING

Methods of Checking Battery Condition

State of Charge

Syringe Hydrometer

Digital Voltmeter

Five Ball Hydrometer

100% Charged w/ Sulfate Stop

1.280

12.80v

Five Balls Floating

100% Charged

1.265

12.60v

Four Balls Floating

75% Charged

1.210

12.40v

Three Balls Floating

50% Charged

1.160

12.10v

Two Balls Floating

25% Charged

1.120

11.90v

One Ball Floating

0% Charged

Less than 1.100

Less than 11.80v

Zero Balls Floating

Summary of Contents for YARD CRUISER YZ13331BE

Page 26: ...26 PRIMARY MAINTENANCE...

Page 27: ...27 PRIMARY MAINTENANCE...

Page 28: ...28 PRIMARY MAINTENANCE...

Page 29: ...29 PRIMARY MAINTENANCE...