13

Section 4 - REPAIR & ADJUSTMENTS

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine and blade running. STOP engine

and blade. Disconnect spark plug wire and secure

away from spark plug. Engine and components are

HOT. Avoid serious burns, allow sufficient time for all

components to cool.

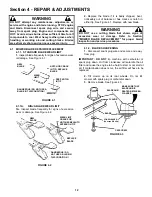

4. Sharpen blade on a grinding wheel at an angle of

22 to 28 degrees. DO NOT sharpen blade beyond

original cutting edge. See Figure 4.4.

FIGURE 4.4

5. Check blade for balance. If necessary, correct

balance by grinding heavy end of blade.

6. Reinstall blade. See Figure 4.1. Check torque of

blade retaining cap screw. Recommended torque

should be 30 to 40 ft. lbs.

NOTE: The following sections 4.2 through

4.4 are for self-propelled models.

4.2 WHEEL DRIVE CONTROL ADJUSTMENT

1. The wheel drive control is properly adjusted when

there is 1/16” to 1/8” clearance between the inside of

the spring hook and the inside of the clutch cable

eye with the wheel drive control released. See

Figure 4.5.

FIGURE 4.5

2. To adjust, unhook upper spring from cable eye

and rotate spring in direction required to extend

or shorten spring length.

3. Rehook upper spring to cable eye and check

clearance. Repeat procedure if required.

NOTE: The vinyl spring cover should be kept over the

spring at all times except for adjustments.

4. If the wheel drive control fails to return quickly to

the “OFF” position when released, check for binding

at the cable holdings located on the side of the right

handle. The upper clip should be located 2” below

the upper knob; the lower clip should be 4” above

the lower knob. The cable should slide freely with

the clips installed at these locations.

CLUTCH CABLE

EYE

CLUTCH CABLE

VINYL SPRING COVER

1/16” TO 1/8”

CLEARANCE

UPPER

SPRING

LOWER

SPRING

SPRING HOOK

CABLE

CLUTCH CABLE EYE

DO NOT SHARPEN

BEYOND ORIGINAL

CUTTING EDGE

22 TO 28º

BLADE TIP

ORIGINAL CUTTING EDGE

END VIEW OF

BLADE ASSEMBLY

Summary of Contents for FRP216012E

Page 24: ...24 PRIMARY MAINTENANCE...

Page 25: ...25 PRIMARY MAINTENANCE...

Page 26: ...26 PRIMARY MAINTENANCE...

Page 27: ...27 PRIMARY MAINTENANCE...