23

Section 5 - ADJUSTMENTS & REPAIR

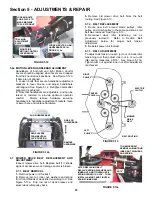

FIGURE 5.12

5.6a MOTION LEVER HANDLEBAR ALIGNMENT

Handlebars of both left and right Motion Control

Levers should be aligned when levers are dropped

from their neutral lock positions. See Figure 5.12a.

If bars are not aligned:

1.

Loosen bolts that secure handlebar adjustment

brackets to lever blocks, and adjust handlebars

until aligned. See Figure 5.12. Retighten bolts after

alignment is achieved.

2.

Note that handlebars are adjustable, and can be

raised or lowered to provide optimum operator

comfort. Simply remove hardware securing

handlebars to handlebar adjustment brackets, raise

or lower bars, and replace hardware.

FIGURE 5.12a

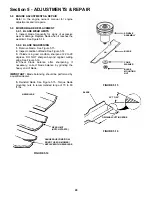

5.7 MOWER DRIVE BELT REPLACEMENT AND

ADJUSTMENT

Inspect mower drive belt. Replace belt if it shows

signs of excessive wear, damage and/or is broken.

5.7.1. BELT REMOVAL

1.

Remove power unit footrest.

2.

Remove jam nut, inner nut, washers and spring

from front threads of deck idler tensioning rod. See

Figure 5.13a. Slip rod out of deck bracket, and

swivel deck idler pulley back.

3.

Remove old mower drive belt. Note the belt

routing. See Figure 5.13.

5.7.2. BELT REPLACEMENT

1.

Route new belt around blade pulleys, idler

pulley, and clutch pulley in the same position as old

belt was removed. See Figure 5.13.

2.

Reconnect deck idler tensioning rod as

previously removed. Refer to Section ‘Belt

Adjustment’ below for proper belt tension

adjustment.

3.

Reinstall power unit footrest.

5.7.3. BELT ADJUSTMENT

To adjust belt tension, loosen jam nut on deck idler

tensioning rod, then adjust inner nut in or out until

idler spring measures 2-5/16”. See Figure 5.13a.

Tighten jam nut against inner nut after adjustment

is achieved.

FIGURE 5.13

FIGURE 5.13a

BELT ROUTING

TRACKING

ADJUSTMENT

PLATE

ELECTRIC

CLUTCH

CENTER

PULLEY

RIGHT

PULLEY

LEFT

PULLEY

MOWER

DRIVE

BELT

RIGHT SIDE

MOTION CONTROL

LEVER BLOCK

TO REMOVE BELT,

REMOVE JAM NUT AND

INNER NUT, WASHERS

AND SPRING

LOOSEN BOLTS. ALIGN

HANDLEBARS AS IN

FIGURE 5.12a

DROP LEVERS

FROM NEUTRAL

LOCK POSITION

ALIGN HANDLEBARS

REMOVE

HARDWARE

RAISE OR

LOWER BARS

LOOSEN BOLTS.

SLIDE PLATE TO

MAKE MACHINE

TRACK STRAIGHT

AFTER REPLACING BELT,

REPLACE SPRING, WASHERS AND

INNER NUT, AND TIGHTEN UNTIL

SPRING LENGTH IS 2-5/16”. THEN

INSTALL JAM NUT AND TIGHTEN

AGAINST INNER NUT.

2-5/16”

Summary of Contents for CZT19480KWV, CZT19481KWV, HZT2

Page 33: ...33 PRIMARY MAINTENANCE...

Page 34: ...34 PRIMARY MAINTENANCE...

Page 35: ...35 PRIMARY MAINTENANCE...

Page 36: ...36 PRIMARY MAINTENANCE...

Page 38: ...38 NOTES...

Page 39: ...39 NOTES...