22

Section 5 - ADJUSTMENTS & REPAIR

WARNING

DO NOT attempt any maintenance, adjustments or

service with engine running. STOP engine. STOP

blades. Set brake. Remove key. Remove spark plug

wires and secure away from spark plugs. Engine

and components are HOT. Avoid serious burns,

allow sufficient time for all parts to cool.

5.3 TRACTION BELT TENSION

The traction drive belt tension does not require

adjustment. If the belt is slipping, it will have to be

replaced.

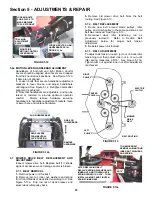

5.4 TRACTION BELT REPLACEMENT

1.

Remove mower drive belt from around clutch

pulley. See Figure 5.10. Refer to Section “MOWER

DRIVE BELT REPLACEMENT AND

ADJUSTMENT”.

2.

Turn lock nut out to the end of eyebolt, reducing

spring tension. Unhook traction idler spring from bolt

in frame. See Figure 5.10.

3.

Remove anti-rotation bracket. See Figure 5.10.

4.

Disconnect the electric clutch from main wire

harness.

5.

Remove traction belt from around engine pulley

and hydro pumps.

6.

Install new belt and route around engine pulley

and hydro pump pulleys.

7.

Reconnect electric clutch to main wire harness.

8.

Reinstall anti-rotation bracket and tighten nuts

securely.

9.

Reattach traction idler spring. Run lock nut all

the way to the end of the threads on the eyebolt.

See Figure 5.10.

10.

Reinstall mower drive belt onto clutch pulley.

Refer to Section “MOWER DRIVE BELT

REPLACEMENT AND ADJUSTMENT”.

FIGURE 5.10

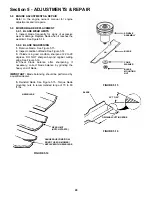

5.5 BLADE

BRAKE/ELECTRIC CLUTCH ADJUSTMENT

The blade switch engages the electric clutch when

pulled out to the “ON” position. When the blade

switch is in the “ON” position the cutting blade(s)

are engaged. The blade switch disengages the

electric clutch when the blade switch is pushed in

to the “OFF” position. When the blade switch is in

the “OFF” position the cutting blade(s) are

disengaged. The electric clutch is adjustable. The

blades should stop rotation in 5 seconds or less. If

the electric clutch fails to stop the blades rotation in

5 seconds, adjustment is necessary.

1.

Insert a feeler gauge into the three slots on the

electric clutch.

2.

Check gap through all three slots in the side of

the clutch. The gap should be set at .015.

3.

If gap is incorrect rotate nuts in or out to achieve

the correct gap. See Figure 5.11.

NOTE:

Electric Clutch is shown removed from the

machine. Removal is not necessary for adjustment.

FIGURE 5.11

5.6 TRACKING

ADJUSTMENT

If the machine does not track straight when the

Motion Control Levers are in the maximum forward

speed position, perform the following adjustment.

Rear tire pressure must be set to 12 PSI before

making this adjustment.

1.

Loosen bolts that secure adjustment plates and

slide plates all the way forward. Retighten bolts.

See Figure 5.12.

2.

Start machine and drive in smooth flat open area

at maximum forward speed.

3.

If machine tracks to the right, loosen bolts that

secure the left adjustment plate. Move plate

rearward to slow the left wheel. Retighten bolts.

4.

If machine tracks to the left, loosen bolts that

secure the right adjustment plate. Move plate

rearward to slow the right wheel down. Retighten

bolts. See Figure 5.12.

5.

Drive machine again. Repeat adjustment as

necessary until machine tracks straight.

REMOVE ANTI-

ROTATION BRACKET

INSERT FEELER GAUGE.

GAP SHOULD BE .015

ROTATE NUTS

IN OR OUT

TO ACHIEVE

CORRECT GAP

UNHOOK TRACTION

DRIVE IDLER SPRING

EYEBOLT

REMOVE MOWER DRIVE BELT

FROM AROUND CLUTCH PULLEY

LOOSEN

LOCK NUT

Summary of Contents for CZT19480KWV, CZT19481KWV, HZT2

Page 33: ...33 PRIMARY MAINTENANCE...

Page 34: ...34 PRIMARY MAINTENANCE...

Page 35: ...35 PRIMARY MAINTENANCE...

Page 36: ...36 PRIMARY MAINTENANCE...

Page 38: ...38 NOTES...

Page 39: ...39 NOTES...