16

Section 4 - MAINTENANCE

4.3.3. RIDING MOWER - LUBRICATION

1. Front Wheel Bearings

Lubricate with Kendall NLGI No. 2 lithium grease or

equivalent, from a grease gun. See Figure 4.5.

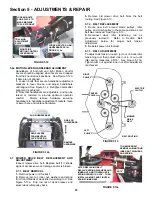

FIGURE 4.5

2. Hydro Pumps

Check the level of the fluid in the fluid reservoir. Wipe

away all dirt and debris from around reservoir cap

before removing. Oil must remain absolutely clean!

Check with machine on a level surface with engine

“OFF”. Fill reservoir as needed to bring level up. The

reservoir is properly filled when the fluid level is 1½”

below the top of the filler neck.

DO NOT OVER FILL.

Use clean, fresh premium automotive oil having a

viscosity equivalent to SAE 20W50 API SL. The fluid

should be chemically stable, incorporating rust and

oxidation inhibitors. Make sure funnels, pouring spouts

and oil can are completely clean. Reinstall reservoir

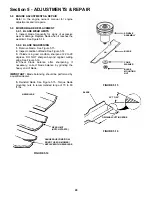

cap. See Figure 4.6.

3. Other Lubrication Points

Lubricate machine caster wheel shafts and traction

idler arm with Kendall NLGI No. 2 lithium grease or

equivalent, from a grease gun. See Figure 4.7.

4.4 BEFORE OPERATING MACHINE

1.

Clean all dirt and debris from around the two

hydraulic fluid reservoir, especially around the top and

cap area.

2.

Clean all dirt and debris from the cooling fins on the

engine and from both hydraulic pumps.

4.5 ANNUALLY (END OF EACH SEASON)

Perform all maintenance as described in Section

“AFTER EVERY 25 OPERATING HOURS”. Refer to

Section “Service Schedule”.

4.5.1. ENGINE

Service engine according to engine owner’s manual.

FIGURE 4.6

FIGURE 4.7

(Continued on next Page)

LUBRICATE

BEARINGS

FRONT

WHEEL

LUBRICATE

CASTER WHEEL

LUBRICATE TRACTION

DRIVE IDLER ARM

(GREASE FITTING

LOCATED ON BOSS

ABOVE IDLER ARM)

ELECTRIC

CLUTCH

HYDRAULIC FLUID RESERVOIR

Summary of Contents for CZT19480KWV, CZT19481KWV, HZT2

Page 33: ...33 PRIMARY MAINTENANCE...

Page 34: ...34 PRIMARY MAINTENANCE...

Page 35: ...35 PRIMARY MAINTENANCE...

Page 36: ...36 PRIMARY MAINTENANCE...

Page 38: ...38 NOTES...

Page 39: ...39 NOTES...