12

Section 3 - OPERATING INSTRUCTIONS

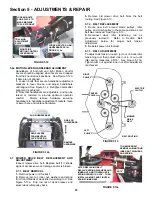

3.3 CUTTING HEIGHT ADJUSTMENT

1.

Adjust cutting height, as desired, to any position,

using deck lift lever. IMPORTANT: There is a foot

assist pedal located to the right front side of the

footrest. Always use this assist pedal to raise or

lower the deck to the desired cutting height. See

Figure 3.10.

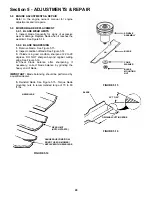

2.

Insert the stop pin to desired cutting height. See

Figure 3.11.

NOTE:

The engine does not have to be running to adjust

cutting height.

FIGURE 3.10

FIGURE 3.11

WARNING

DO NOT make turns at high speed. Slow machine

motion. Move motion control lever gently and with

caution. DO NOT make sudden changes in speed or

direction.

3.4 OPERATION- MOTION CONTROLS

This machine is equipped with dual hydrostatic wheel

drive transmissions. Each hydro pump is controlled by a

separate motion control lever. The left lever controls the

left wheel drive hydro pump and the right lever controls

the right wheel drive hydro pump. These levers control

the direction of motion, Forward & Reverse, and the

speed of motion. Move both levers forward to propel the

machine forward. Move both levers rearward to propel

the machine in reverse. The speed of motion is

continuously variable from neutral (zero) to the

maximum. Moving the levers farther from the neutral

position will cause the speed of motion to increase. To

turn, move the lever on the side to which you want to

turn slightly rearward of the other lever. Move levers

slowly and carefully. DO NOT make sudden changes in

speed or direction. Always slow machine motion before

turning. To stop the motion of the machine, bring both

motion control levers to the neutral position. Engage

parking brake.

3.4.1. DRIVING MACHINE

1.

Start engine. Release parking brake.

2.

Drop motion control levers down from neutral

lock positions. See Figure 3.12.

3.

Move motion control levers gently and with

caution in desired direction. See Figure 3.12.

FORWARD

- Move both control levers forward.

REVERSE -

Move both control levers rearward.

LEFT TURN

- Move left control rearward or move

right control lever forward.

RIGHT TURN

- Move left control forward or move

right control lever rearward.

ZERO RADIUS TURN

- Move one control lever

forward and move the other control lever rearward

simultaneously.

FIGURE 3.12

WARNING

Zero-turning the machine at any speed can result in

operator disorientation, or in operator being thrown

from the machine. Exercise extreme caution when

executing a zero-turn.

REARWARD

MOVEMENT

FORWARD

MOVEMENT

DECK LIFT LEVER

SHOWN IN HIGHEST

POSITION

DECK LIFT

ASSIST PEDAL

6 HOLE POSITIONS

FOR STOP PIN

Summary of Contents for CZT19480KWV, CZT19481KWV, HZT2

Page 33: ...33 PRIMARY MAINTENANCE...

Page 34: ...34 PRIMARY MAINTENANCE...

Page 35: ...35 PRIMARY MAINTENANCE...

Page 36: ...36 PRIMARY MAINTENANCE...

Page 38: ...38 NOTES...

Page 39: ...39 NOTES...