5

Start Up Mode

Sloan OPTIMA Plus

®

EBF-85 and EBF-187 Electronic, Sensor Activated

Lavatory faucets use

Adaptive Sensing

technology to automatically set its

sensing range once power is supplied to the faucet. No mechanical range

adjustments are required. The faucet automatically adapts its range to its

surrounding environment.

Self-Calibration Procedure

When the Battery Compartment is assembled to the Valve Module with full

electrical power, the faucet initiates a self-calibration mode and uses

BEEPs

to indicate the status of this mode. To prevent improper calibration,

ensure that the Spout is centered properly and that no targets are in the

detection range of the sensor when the electrical connections are made.

An initial series of

BEEPs

indicates that power is being supplied to the

faucet. For the next thirty (30) seconds, the sensor determines the most

suitable range setting for its environment. Water will not flow from the

faucet during this automatic range calibration. After the range is calibrated,

a second series of

BEEPs

indicates that the faucet is ready for use. Under

normal operation, this faucet adapts its range to changes in the

environment.

If manually starting the recalibration procedure is necessary, unscrew the

Coupling Ring to break the electrical connection between the Battery

Compartment and the Valve Module. Reconnect the electrical connection

by reattaching Battery Compartment (with batteries) to the Valve Module

and tighten the Coupling Ring. The self-calibration procedure should start

automatically after proper electrical connections are made.

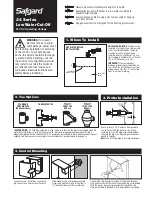

Start-Up

8

A

Remove Spray Head.

B

Open supply stop(s), then activate Faucet for 30 seconds by

placing hands in front of sensor. The Solenoid Valve should

“click,” the Valve Module should “beep” and water should flow

from the Spout. If this does not occur, refer to the Troubleshooting

section of this instruction instructions.

C

Close supply stop(s) and reinstall Spray Head in Spout using Key

provided.

D

Reopen supply stop(s), activate Faucet and check for leaks.

9

Test Faucet Operation

1. A continuous invisible beam of infrared

light is emitted from the fiber optic

“eyes” located on the front of the

lavatory faucet.

2. As the user’s hands enter the beam’s

effective range (beneath the spray head),

the beam is reflected back into the

receiver “eye” and activates the solenoid

valve allowing tempered water to flow

from the faucet into the sink. Water will

flow until the hands are removed or until

the faucet reaches its automatic time out

limit setting.

3.

When hands are moved away from the

Sensor, the loss of reflected light initiates

an electrical signal that deactivates the

Solenoid Valve, shutting off the water

flow. The Circuit then automatically

resets and is ready for the next user.

CARE AND CLEANING OF CHROME AND

SPECIAL FINISHES

DO NOT use abrasive or chemical cleaners (including chlorine bleach) to

clean faucets that may dull the luster and attack the chrome or special

decorative finishes. Use ONLY soap and water, then wipe dry with clean

cloth or towel.

While cleaning the bathroom tile, protect the faucet from any splattering of

cleaner. Acids and cleaning fluids will discolor or remove chrome plating.