11

®

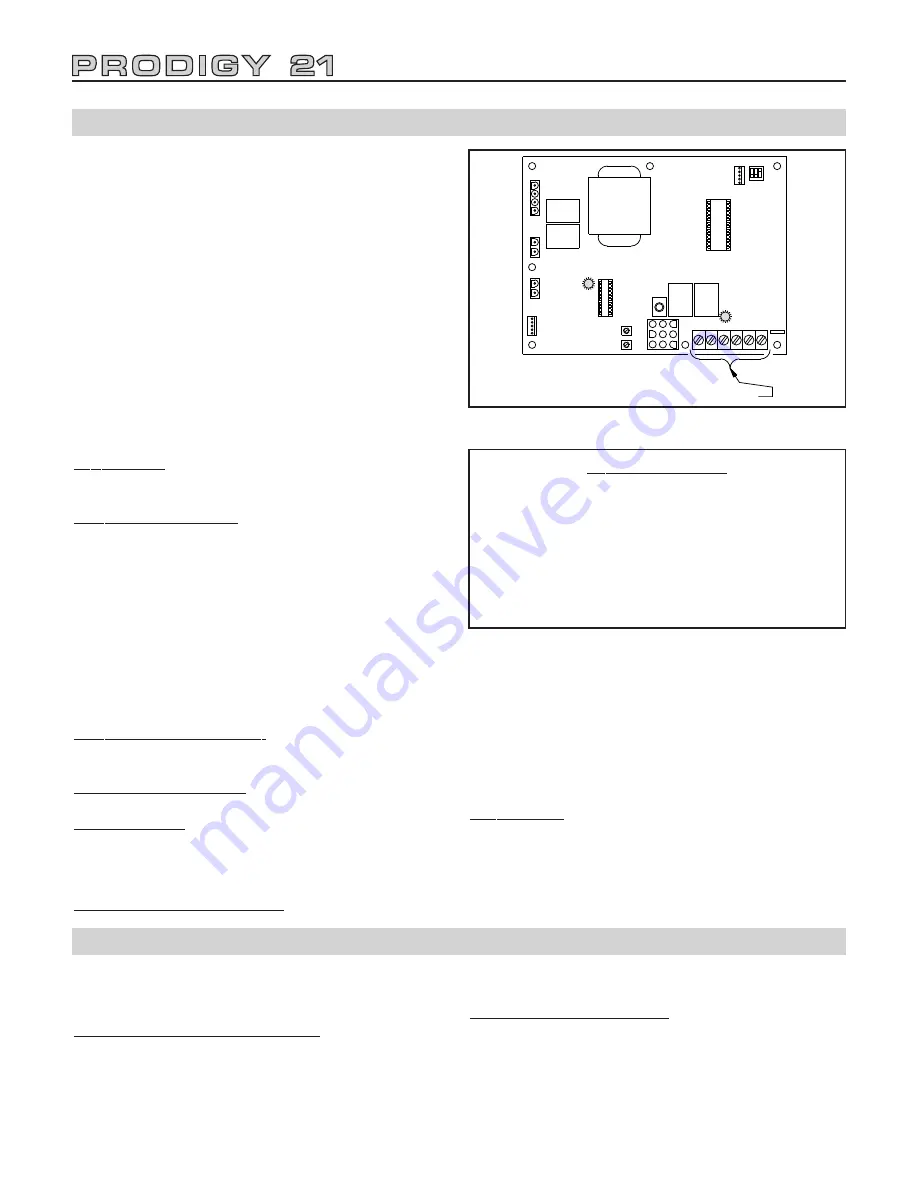

STEP 7: INSTALL POWER AND THERMOSTAT WIRING

LO

HI

FT1 FT2 T1 T2

A1 A2

A

U

T

O

/M

A

N

C

A

L

/O

P

L

O

/H

I

Thermostat & Alarm Terminals

Figure 16: Electronic Boiler Control Board

DANGER: BEFORE WIRING, ALWAYS TURN OFF

ELECTRIC POWER SUPPLY. OTHERWISE, SHOCK

OR DEATH CAN RESULT.

WARNING: DO NOT USE BOILER TRANSFORMER

TO POWER EXTERNAL ACCESSORIES (i.e. ZONE

VALVES, RELAYS). OVERLOADED/BURNED-OUT

TRANSFORMER CAN RESULT.

WARNING: DO NOT CONNECT WIRES CARRYING

POWER FROM AN EXTERNAL SOURCE TO THER-

MOSTAT OR AQUASTAT TERMINALS. SEVERE DAM-

AGE TO THE CONTROL BOARD CAN OCCUR.

Boiler must be electrically grounded in accordance with

the requirements of the authority having jurisdiction or,

in the absence of such requirements, with the National

Electrical Code, ANSI/NFPA 70.

Power Supply: A separately fused circuit is recommend-

ed. Use a standard 15-amp fuse or breaker and 14-

gauge conductors in BX cable or conduit.

Thermostat Connections: The boiler will run at high or

low fire, depending on space heating needs, when the

T1 and T2 terminals are closed. Connect low voltage

wiring from space heating zones to T1 and T2 terminals

on control board. Wire connections to T1 and T2 termi-

nal block must be from an isolated circuit. DO NOT

BRING VOLTAGE FROM AN EXTERNAL SOURCE

HERE. Wires should be only run from thermostats, zone

valve end switches, or circulator end switches. 3 wire

zone valves which do not have isolated end switches

cannot be used unless a relay is added with the dry

contacts wired to T1 and T2.

Thermostat Heat Anticipator: For zoned system, set to

match amp draw of zone valve or circulator relay. For a

non-zoned system, set to .3 amps.

Circulator Relay on Board: DO NOT exceed 5

amp/120V max. rating.

Wiring Diagrams: See index on Page 20 for zoning with

zone valves, indirect-fired water heater and reference

boiler diagram.

OPTIONS AVAILABLE

Domestic Hot Water Installation: The boiler will run at

high fire mode for maximum recovery of the Storage

Tank when the A1 and A2 terminals are closed.

Connect zone valve end switch to A1 and A2 terminals

on electronic boiler control board. Water heater thermo-

stat operates zone valve. DO NOT bring power from an

external source to these terminals. Note: 3 wire zone

valves which do not have isolated end switches cannot

be used unless a relay is added with the dry contacts

wired to T1 and T2.

Alarm System: A remote-type alarm device may be con-

nected to the boiler that will be activated if the boiler

shuts down due to a malfunction. FT1 and FT2 termi-

nals on electronic boiler control board are a dry contact

(5 amp 120 V max) that makes on a system fault or

power outage.

STEP 8: INSTALL JACKET ENCLOSURE

Power Connections

• Remove electrical junction box cover.

• HOT CONNECTION LEAD IS BLACK.

• NEUTRAL CONNECTION LEAD IS WHITE.

• Connect ground inside box.

DO NOT REVERSE POWER CONNECTIONS; if

reversed, ignition control will not detect a flame and

will go into safety shutdown.

The jacket can also be installed after start-up proce-

dures. Jacket components include boiler enclosure and

front cover.

TO INSTALL BOILER ENCLOSURE

• For side wall venting ONLY, remove appropriate vent

side panel from enclosure (located at top of sides).

• Place enclosure top over top flange of wall panel.

• Slide down until slots (on the insides of enclosure) are

seated in support brackets on mounting panel.

• Attach sheet metal enclosure to wall panel on both

sides with screws.

TO INSTALL FRONT COVER

• Insert the slots in cover bottom over support clips on

sheet metal enclosure bottom.

• Line up temperature/pressure indicator and push

cover in until support clip (at enclosure top) snaps

into slot on cover top.

• Install the 4 LED window plugs into the front cover

holes (if not factory installed).

Summary of Contents for Prodigy 21 KC-45

Page 22: ...22...