49

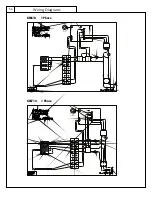

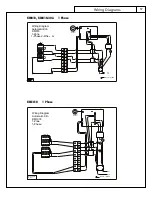

To separate a PK kiln into sections

●

Refer to page 12 for Lid Lifter and lid removal instructions.

●

Remove the screws from the side of the red control box and swing the panel to the side.

●

Number the feeder wires using tape so you can remember where they will be reconnected.

●

Loosen the terminal block lugs that hold the feeder wires. These are located on the fiberglass lined heat

baffle. Remove wires from the three terminal blocks.

●

Slide the thermocouple connectors off the terminal strip.

●

Lift the red control box up to remove it.

●

Unhook the draw pull catches and lift the sections using the handles provided.

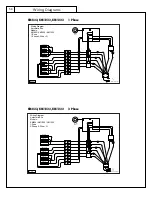

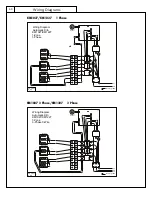

To reassemble PK kilns

●

Stack the sections in original sequence.

●

Place the switch box on its hinges.

●

Reattach the feeder wires in their original positions.

Make sure the connection is very tight to avoid

electrical problems.

●

Reattach the thermocouple wires in their original position, positive to positive and negative to negative.

●

Reattach the screws which secure the control box to the kiln jacket.

Appendices