1

INSTRUCTIONS AND PARTS LIST

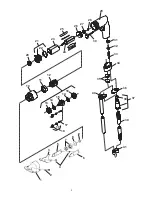

FOR 1446ES AIR SHEAR

(SERIAL “A”)

Form Z545

Date 2003August19/G

Page 1 of 4

Printed In U.S.A.

AIR SUPPLY

The efficiency and life of this tool depends on the proper

supply of clean, dry, lubricated air at about 90 lbs. P.S.I.,

although higher or lower pressures may be used. The use

of an air line filter, pressure regulator and lubricator is

recommended.

Before connecting the tool, blow the air line to remove

water and dirt which may have accumulated. This is

especially important for a new line or when the line has not

been used for some time.

HOSE AND HOSE CONNECTION

The air supply hose is 3/8" I.D. If extension hose is neces-

sary, use 1/2" hose, with couplings not less than 3/8" I.D.

LUBRICATION

An oil supply to the air motor is important. SIOUX air line

lubricators are recommended. Adjust to deliver 2 drops of

SIOUX Air Motor Oil No. 288 per minute. When air line

lubricator is not used squirt several drops of oil into the air

inlet before using. Shear head must be lubricated after

every 40 hrs. of operation, with SIOUX Grease No. 289A.

SAFETY

1.

Keep work area clean.

2.

Do not force tool.

3.

Secure work where possible- use clamps or vise.

4.

Keep tools sharp and in good shape.

5.

Disconnect tools when not in use.

6.

The use of accessories not provided or specified may

be hazardous.

7.

Use goggles or safety glasses.

WARNING

Designed to cut only up to 16 gauge steel, plastic and

associated materials up to 3/32" thick. Failure to grease

could void warranty. Sioux Tools cannot assume responsi-

bility for damage to or malfunction of a shear head used in

combination with any drill other than those regularly sup-

plied by Sioux Tools.

SHEAR HEAD MAINTENANCE INSTRUCTIONS

ADJUSTMENT

To adjust the curl of waste material, the left side knife

54500 has elongated holes. Adjustment may be necessary

after changing blades or material being cut. Loosen cap

screws 07102 and tap side knife 54500 either forward or

backward so that curl of waste does not hit shear housing

12598 of work material while cutting.

DISASSEMBLY

To remove 53609 shear head from power unit and dis-

mantle:

1.

Loosen both rear cap screws 07102 three complete

turns.

2.

Remove shear head assembly 53609 from motor by

pulling head firmly forward. Slight twisting action may be

required.

3.

Remove three cap screws 07102 completely from shear

housing 12598. Be careful not to lose rear spacer bush-

ing 54502 when removing rear cap screw.

4.

Remove center blade 54499 from shear housing 12598

by tapping blade gently rearward. Be careful not to lose

spacer bushing 54502 from hole in center blade.

5.

Side Knives 54500 and 54501 will now drop out of shear

housing.

ASSEMBLY

To assemble 53609 shear head and adapt to power unit:

1.

Place the left side knife 54500 into position in the shear

housing.

2.

Insert center cap screw 07102 through housing and blade

just far enough to slip spacer bushing 54502 over cap

screw.

3.

Place right side knife 54501 into position and push cen-

ter cap screw through right side knife. Start cap screw

into insert just enough to hold blades in place.

DO NOT TIGHTEN.

4.

Insert spacer bushing 54502 into hole in center blade

54499 and lubricate with a good grade of bearing grease.

5.

Install center blade 54499 into shear housing 12598 by

tapping blade gently forward using a drift to line up hole

in center blade with forward holes in housing.

6.

Insert and tighten forward cap screw 07102 making sure

spacer bushing 54502 in center blade stays in position.

Apply good grade of bearing grease to clevis in center

blade. WHEN SHEAR HEAD IS PROPERLY AS-

SEMBLED THE CENTER BLADE WILL PIVOT FREELY

IN HEAD.

7.

Insert rear cap screw 07102 into shear housing 12598

but do not completely tighten.

To install shear head assembly 53609 onto power unit:

1.

Make sure rear cap screw and center cap screw 07102

are loosened three complete turns.

2.

Place shear head onto unit and tighten cap screws 07102

snugly to lock head assembly in place. It may be neces-

sary to gently tap the shear head assembly into place if

it does not readily slip onto the power unit.