Chapter 3. Routine Maintenance

3-1

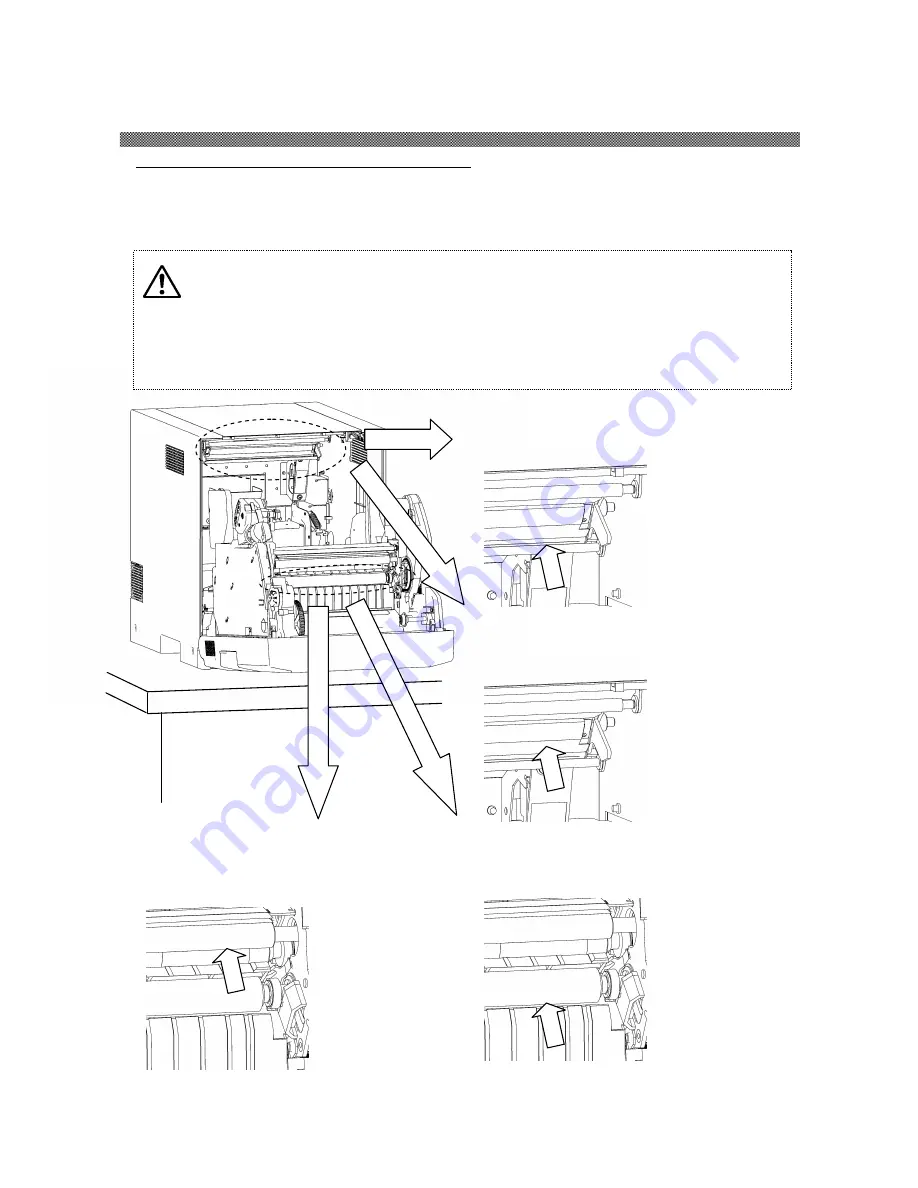

Cleaning of Thermal Head and each Roller

By using thermal transfer technology, daily maintenance is not really necessary if the printer is

being use properly.

However, in order to keep the best print quality, it is recommended to do the cleaning of Thermal

Head, Peeling Roller, Platen, Main Pinch Roller and Cleaning Roller once in a month.

Using gauze, clean the heat element (glass

bar) of the thermal head with isopropyl

alcohol or ethyl alcohol.

Using gauze dipped with isopropyl alcohol or

ethyl alcohol, clean the peeling roller.

Using gauze dipped with isopropyl alcohol

or ethyl alcohol, clean the main pinch

roller.

Using gauze dipped with isopropyl alcohol or

ethyl alcohol, clean the rubber section of the

platen roller.

Caution: Make sure that the power is turned off before starting cleaning.

Thermal Head reaches high temperature just after printing. Do not touch directly

by hand. Make sure that the thermal head has been sufficiently cooled down before

starting cleaning.

When fingerprint stick to the heat element, it can damage the Thermal Head. Do

not touch directly by hand.

Be careful not to be hurt by the projections of the printer.