130

IT

ES

FR

BE

GB

RUS

RO

3.1

ELECTRONIC BOARD

Built according to Low Voltage direc-

tive 2006/95/CEE and powered at

230 Volt, via a transformer it sends

24 Volt power to the following compo-

nents: gas valve, safety thermostat,

heating probe, external temperature

pr obe (optional), wat er pr essur e

tr ansducer, air pr essur e switch,

room thermostat or “Remote Control

Logic”. An automatic and continual

modulation system permits the boiler

t o a d j u s t p o w e r t o t h e v a r i o u s

system or user needs. Electronic

components are guaranteed to ope-

rate in a temperature range from 0

to +60°C.

3.1.1

Malfunctions

Boiler malfunctions or failures can be

indicated by a flashing temperature

LED as shown in fig 12.

3.1.2

Devices

The electronic board is equipped with

the following devices:

–

“HEATING POWER” TRIMMER

(10 fig. 13)

Adjusts maximum heating power. To

increase the value, rotate the trim-

mer clockwise, to reduce it, rotate

the trimmer counter-clockwise.

–

“IGNITION POWER” TRIMMER

(6 fig. 13)

Trimmer to vary the gas valve ignition

pressure level (STEP). According to

the type of gas the boiler is designed

for, the trimmer must be adjusted to

achieve a burner pressure of approxi-

mately 6.5 mm H

2

O for methane gas

and 9.5 mm H

2

O for propane gas

(G31). To increase pressure, rotate

the trimmer clockwise, to reduce it,

rotate the trimmer counter-clockwi-

se. The slow ignition pressure level

can be set during the first five

seconds after the burner is lit.

After setting the ignition pressure

level (STEP) according to the type of

gas, make sure that the heating gas

pressure is still the previously set

value.

–

“ANN. RIT.” CONNECTOR

(5 fig. 13)

The electronic board is program-

med, during heating, with a techni-

c a l b u r n e r d e l a y o f a b o u t 9 0

seconds that is performed both at

cold start and subsequent ignitions.

This is to prevent rapid ignitions and

shutdowns that could, in particular,

occur in systems with high load los-

ses. Each time the boiler restarts,

after the slow ignition, for about 1

minute it will run at minimum modu-

lation pressure before moving to

the set heating pressure.

The addition of a bridge will cancel

both the programmed technical

delay and the minimum pressure

operating period at ignition.

In this case, the time between shut-

d o w n a n d t h e n e x t i g n i t i o n w i l l

depend on a 5°C differential detec-

ted by the heating probe (SM).

–

DIP SWITCH

(13 fig. 13)

For correct module operations, the

dip switches must be positioned as

indicated below:

–

“Modureg Sel.” connector

(14 fig. 13)

The bridge must always be

connec-

ted

.

–

“Albatros” connector

(15 fig. 13)

The bridge must always be off. It is

only engaged in sequence/cascade

installations with several boilers.

WARNING: All the above operations

must be performed by authorised

personnel, otherwise the warranty

shall be invalidated.

3

CHARACTERISTICS

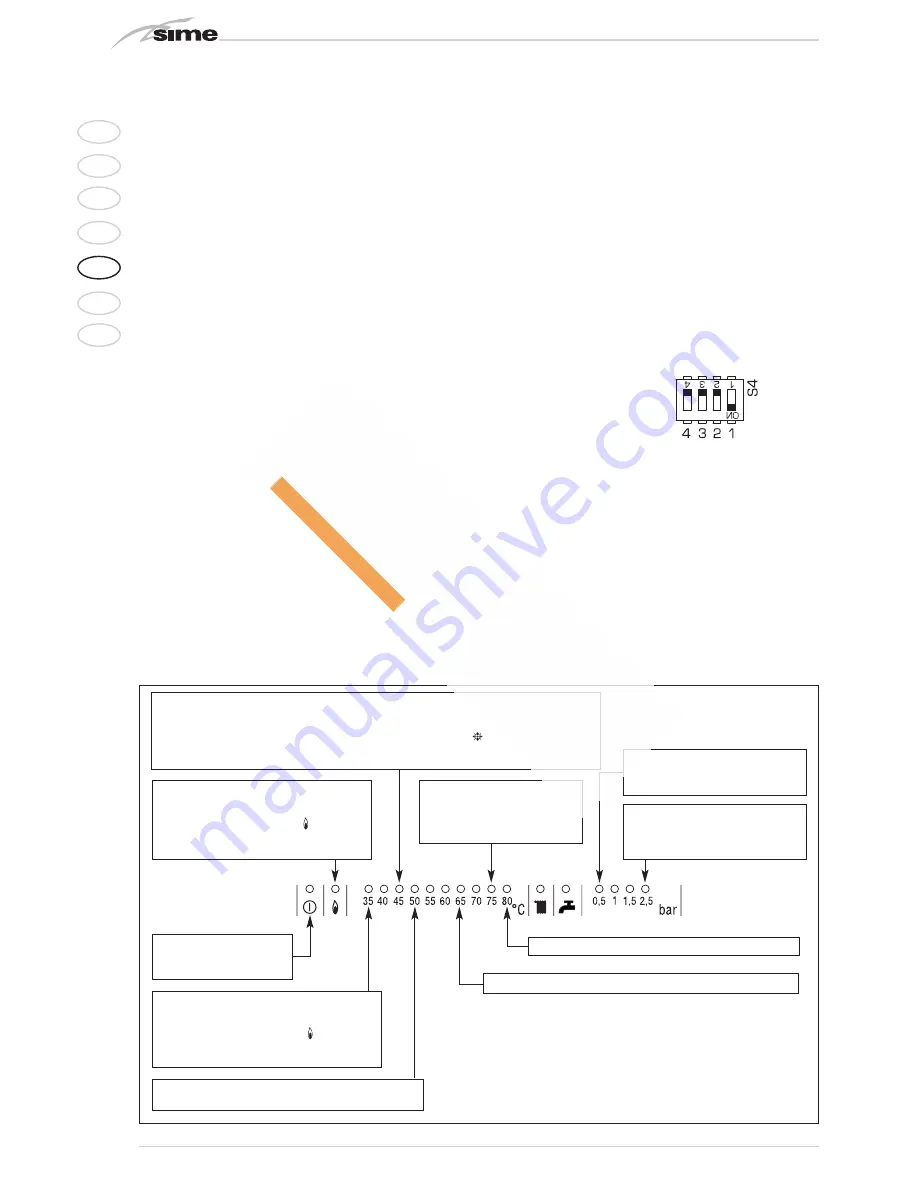

Flashing red led,

communication fault

with “Logica Remote Control”

Green led off if

power is cut-off

Blinking red air pressure switch fault led

Flashing red led, water

pressure is too low (*)

Flashing red led, heating sensor fault (SM)

Flashing red led,

plant safety

valve tripped (*)

Red led on, ignition blocked:

rotate selector CR/OFF/EST/INV/RESET

to release position (

)

to restore operation

Flashing red led, safety stat tripped.

Rotate selector CR/OFF/EST/INV/RESET

to release position (

)

to restore operation

(*) When all 0.5 to 2.5 bar leds are off, check the water pressure transducer

connection.

WARNING: the operation of plants with open vessels is guaranteed only for

static pressures above 0.7 bar.

On model “100 BFR” continuous operation can be guaranteed, even for pres-

sure reductions > 4 bars, by activating jumpers X4 e X25 (fig. 13) only and

electrically disconnecting the connector from the water pressure transducer.

The operating pressure can be measured using the pressure gauge installed

in the plant.

Fig. 12

Flashing red led, flame detection circuit fault

Blinking red fan fault led. 30 minutes after the fan turns off, the board attempts to

restart it. To identify where the fault occurred in sequence/cascade installations, turn

the CR/OFF/INV/RELEASE selector on each module to the (

) position and check

where the red fault led blinks.