Maintenance

20127402

26

GB

8.1

Notes on safety for the maintenance

The periodic maintenance is essential for the good operation,

safety, yield and duration of the burner.

It allows you to reduce consumption and polluting emissions and

to keep the product in a reliable state over time.

Before carrying out any maintenance, cleaning or checking oper-

ations:

8.2

Maintenance programme

8.2.1

Maintenance frequency

8.2.2

Checking and cleaning

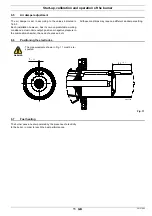

Combustion head

Open the burner and make sure that all components of the com-

bustion head are in good condition, not deformed by the high

temperatures, free of impurities from the surroundings and cor-

rectly positioned.

Boiler

Clean the boiler as indicated in its accompanying instructions in

order to maintain all the original combustion characteristics in-

tact, especially the flue gas temperature and combustion cham-

ber pressure.

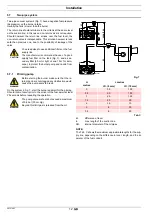

Pump

If the pressure is unstable, or the pump runs noisily, the flexible

hose must be detached from the line filter and the fuel must be

sucked from a tank located near the burner. This measure per-

mits the cause of the anomaly to be traced to either the suction

piping or the pump.

If the problem lies in the suction line, check the filter is clean and

that air is not entering the piping.

Filters

Check the filtering baskets on line and at nozzle present in the

system.

Clean or replace if necessary.

If rust or other impurities are observed inside the pump, use a

separate pump to lift any water and other impurities that may

have deposited on the bottom of the tank.

Nozzles

It is advisable to replace nozzles once a year during periodical

maintenance.

Do not clean the nozzle openings.

Flexible hoses

Check periodically the flexible pipes conditions. They have

to be replaced at least every 2 years.

Check to make sure that the hoses are still in good condi-

tion.

Fuel tank

If water or contamination is present within the fuel tank, it is es-

sential that this is removed before the equipment is to be used.

This is extremely important when light oil containing bio diesel is

in use. If in doubt about how to achieve this then please contact

the fuel or oil tank supplier.

Combustion

Carry out an analysis of the combustion flue gases.

Significant differences with respect to the previous measure-

ments indicate the points where most care should be exercised

during maintenance.

In case the combustion values found at the beginning of the inter-

vention do not respect the standards in force or, in any case, do

not correspond to a proper combustion, contact the Technical As-

sistance Service in order to carry out the necessary adjustments.

Let the burner run at full capacity for about ten minutes, setting all

the elements correctly as explained in this manual.

Then carry out the analysis of the combustion by checking:

•

Smoke temperature at the flue;

•

CO2 content (%);

•

CO content (ppm);

•

Smoke value according to opacity smokes index according to

Bacharach scale.

8

Maintenance

DANGER

The maintenance interventions and the calibration

of the burner must only be carried out by qualified,

authorised personnel, in accordance with the con-

tents of this manual and in compliance with the

standards and regulations of current laws.

DANGER

Turn off the burner's power supply using the main

system switch.

DANGER

Turn off the fuel interception tap.

Wait for the components in contact with heat

sources to cool down completely.

The combustion system should be checked at

least once a year by a representative of the man-

ufacturer or another specialised technician.

The operator must use the required equipment

during maintenance.

Summary of Contents for 8099157

Page 2: ...Istruzioni originali Translation of the original instructions...

Page 30: ......

Page 58: ......

Page 59: ......

Page 60: ...Con riserva di modifiche Subject to modifications...