Installation

20127402

12

GB

5.7

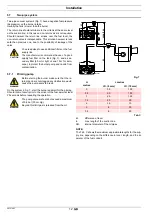

Two-pipe system

Two-pipe vacuum systems (Fig. 7) have a negative fuel pressure

(depression) on the burner intake.

Usually the tank is lower than the burner.

The return line should terminate in the oil tank at the same level

as the suction line; in this case a non-return valve is not required.

Should however the return line arrives over the fuel level, the

non-return valve is indispensable. This solution however is less

safe than previous one, due to the possibility of leakage of the

valve.

5.7.1

Priming pump

On the system in Fig. 7, start the burner and wait for the priming.

Should lockout occur prior to the arrival of the fuel, await at least

20 seconds before repeating the operation.

Tab. C

H

difference of level

L

max. length of the suction line

I.D.

internal diameter of the oil pipes

NOTE:

The Tab. C shows the maximum approximate lengths for the sup-

ply line, depending on the difference in level, length, and the di-

ameter of the fuel conduit.

CAUTION

You are advised to use additional filters on the fuel

supply line.

The manufacturer recommends the use of a good

quality fuel filter on the tank (Fig. 7), and a sec-

ondary filter (60 m for light oil and 15 m for kero-

sene), to protect the burner pump and nozzle from

contamination.

WARNING

Before starting the burner make sure that the re-

turn pipe-line is not clogged any obstruction would

cause the pump seals to break.

WARNING

The pump vacuum should not exceed a maximum

of 0.4 bar (30 cm Hg).

Beyond this limit gas is released from the oil.

H

metres

L metres

I.D. (8 mm)

I.D. (10 mm)

0

35

100

0.5

30

100

1

25

100

1.5

20

90

2

15

70

3

8

30

3.5

6

20

H

max. 4 m

H

D10011

Fig. 7

Summary of Contents for 8099157

Page 2: ...Istruzioni originali Translation of the original instructions...

Page 30: ......

Page 58: ......

Page 59: ......

Page 60: ...Con riserva di modifiche Subject to modifications...