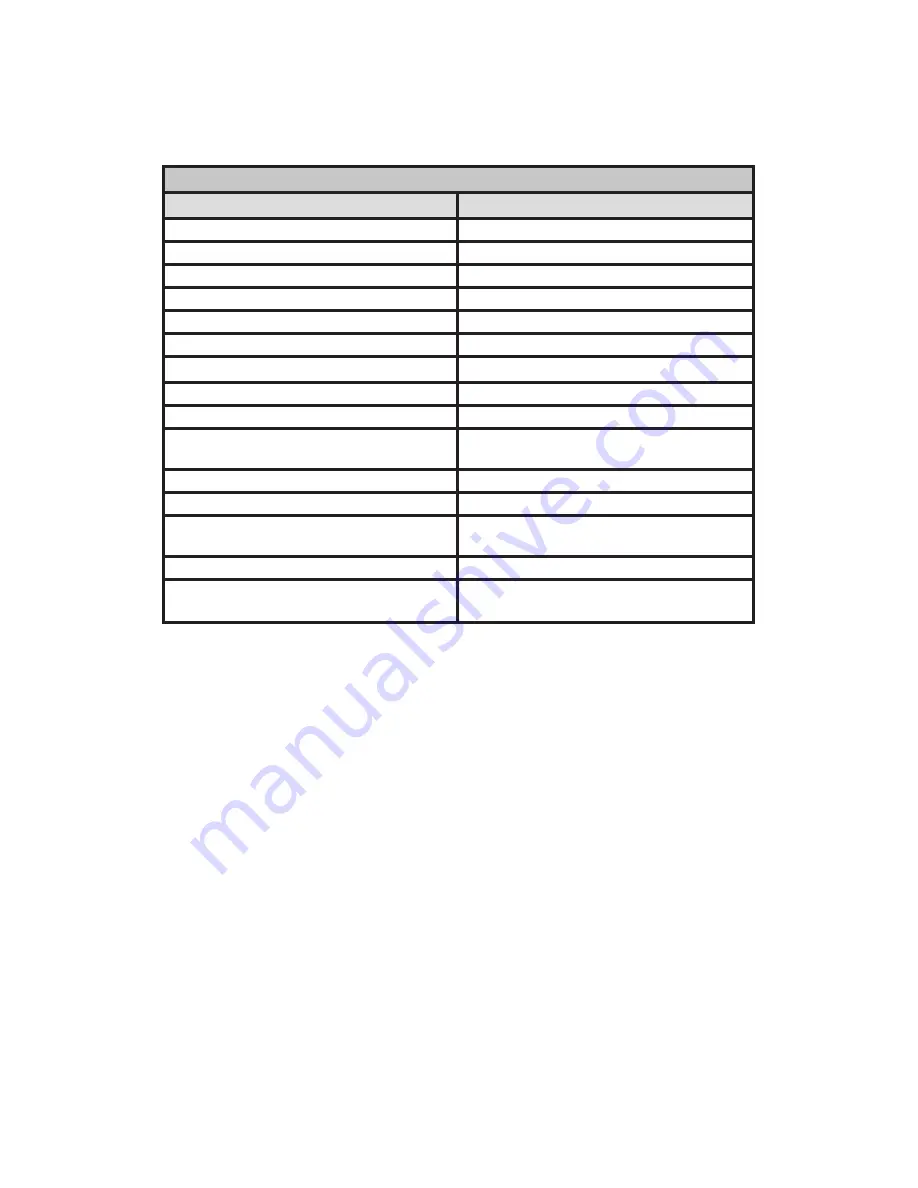

Appendix A

Bobcat Specifications

Model Name/No.

BA-60

Max. Cutting Width

590mm(23.23in)

Max. Media Loading Width

719mm(28.3in)

Min. Media Loading Width

124mm(4.88in)

Acceptable Material Thickness

0.8mm (0.03 in)

Number of Pinch Rollers

2

Motor

DC Servo Control

Cutting Force

0~300 g

Max. Cutting Speed

Up to 600 mm /sec. (23.62 ips)

Memory

16MB ( 4MB in buffer )

Interfaces

USB 1.1 & Parallel (Centronics) & Serial

(RS-232C)

Commands

HP-GL, HP-GL/2

Control Panel

10 Control Keys , 6 LED’s

Dimension (HxWxD)

220x 879x258mm

8.67 x34.61x10.16in

Net Weight

11.2kg

Power Supply

AC 100-240V, 50~60 Hz (auto switching)

*This specification is subject to change without prior notice.