9

PARTS REMOVAL AND REPLACEMENT

WEAR SAFETY GLASSES WITH SIDE SHIELDS WHICH CONFORM TO ANSI STANDARD

Z87.1. FAILURE TO WEAR SAFETY GLASSES COULD RESULT IN SEVERE PERSONAL

INJURY. PROTECT YOUR EYES. READ GENERAL SAFETY INSTRUCTIONS IN THE FRONT

OF THIS MANUAL

•

Only trained people should service machine

•

Unless specified, shutoff and lock out all electrical power.

•

Follow all service instructions.

•

Use Correct tools.

•

Never adjust, repair or oil moving machinery

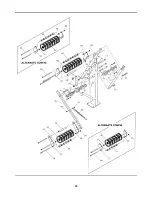

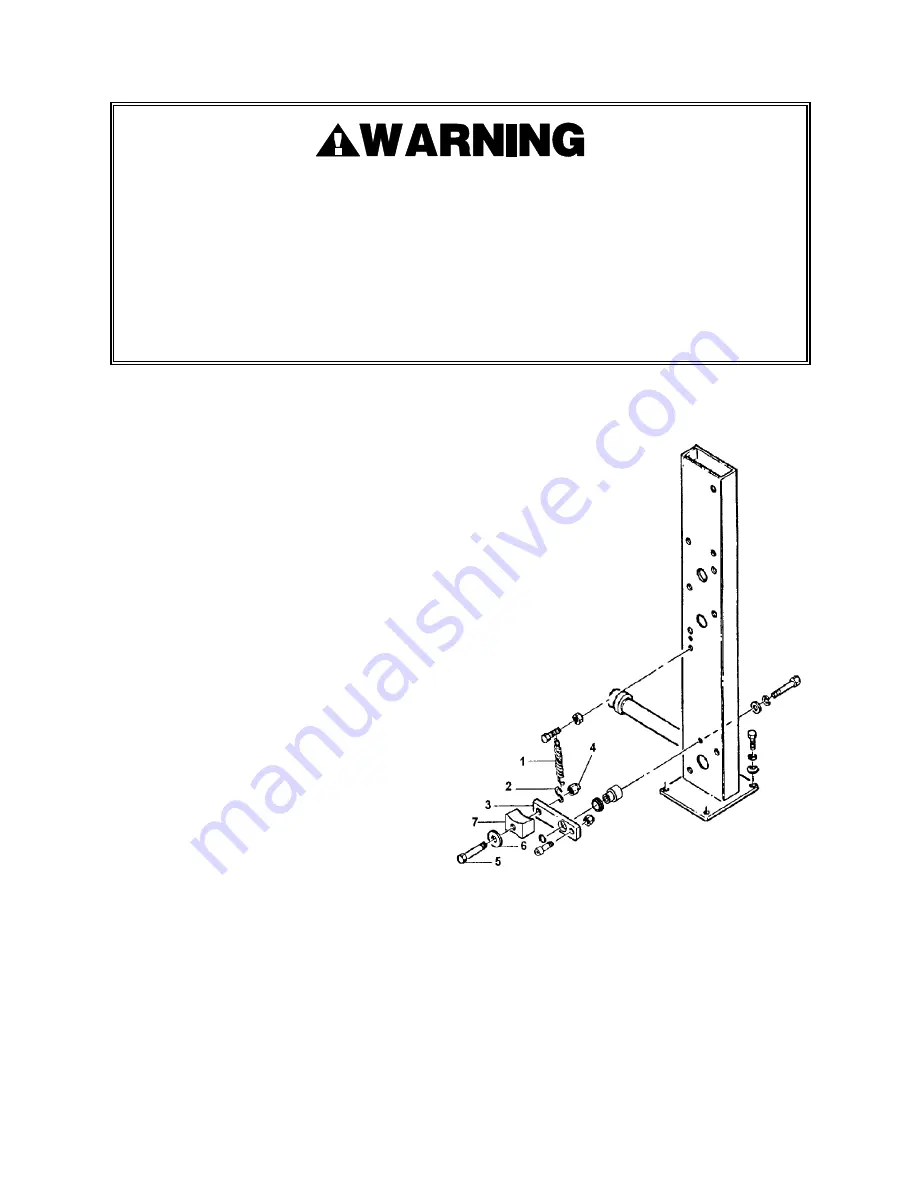

BRAKE BLOCK

To remove and replace the brake block:

1. Lift the dancer arm and hang it on the

lacing hatch. This will discharge the

brake.

2. Disconnect the extension spring (1) at the

S-hook (2) on the brake lever (3).

3. Remove the 1/2-20 stop nut (4), the hex

head cap screw (5), the flat washer (6) and

the worn brake block (7) from the brake

lever.

4. Install the brake block and reassemble all

parts. At this point, just snug the stop nut.

5. Turn the brake block so that the rolled

edge of the inner flange will make as much

contact with the brake block as possible.

6. Attach the extension spring to the S-hook.

7. Tighten the stop nut until the brake block

is firmly held between the flat washer and

brake lever.

8. Release the dancer arm and return the lacing latch to its storage position on the upper arm.

9. Readjust the brake block pressure, if needed. Refer to the Adjustments Section for details.

Summary of Contents for 513684

Page 1: ...PSD 109 STRAP DISPENSER ...

Page 4: ...4 RIGHT HAND ORIENTATION LEFT HAND ORIENTATION MAJOR COMPONENTS ...

Page 15: ...15 BLANK ...

Page 17: ...17 ...

Page 19: ...19 ...

Page 21: ...21 ...

Page 23: ...23 ...