5

hole locations onto the mounting blocks.

Remove the servo and drill pilot holes for the servo mounting

screws into the wood mounting blocks, using a #60 (1 mm) bit.

Use the mounting screws that came with your servo to secure the

servo to the mounting blocks.

Repeat this same procedure with the remaining aileron servo and

servo hatch.

❑

9) In this step, the servo arms will be centered onto the servo

output shaft. First, remove the servo output arm retaining screws

and remove the servo output arms.

Connect the two aileron

servos leads into a standard "Y" harness. Plug the "Y" harness

into the receiver. Turn your transmitter on and center the aileron

trim to neutral. Connect the receiver to a 4.8v battery pack. With

the system now on and working, reattach the two servo output

arms onto the two aileron servos, with the arms at 90

O

(or as close

to 90

O

as possible) and reinstall the output arm retaining screws

into each servo. If your radio system has "sub trim" capability, use

this feature to further center the output arms at 90

O

to the servo

body and centered within the servo hatch slot. Once the output

arms are both centered, cut off the opposite, unused end of each

arm. This ensures that the arm will not contact the covering on the

inside top of the wing when the servo tray is installed. Turn the

radio system off and unplug the servo leads from the "Y" harness.

❑

10) Connect a 6" servo lead extension onto each aileron servo

lead.

We always suggest securing these extensions at the

connectors, using a length of heat shrink tubing. This ensures that

the connection remains secure.

❑

11) On the top surface of the wing, near the center joint, you will

be able to feel the location of two 1/2" diameter holes through the

covering. These are the exit holes for the aileron servo leads. Use

a sharp #11 blade to remove the covering from these holes. You

should then be able to see a small stick tack-glued to the inside top

sheeting with a string attached to it. This is the pull string, used to

pull the aileron servo leads through the wing ribs.

❑

12) Inside the aileron servo bay in each wing panel, the other

end of this string is attached to a small tack-glued stick. Break this

stick loose and unwind the string from the stick. This end of the

string is secured firmly to the connector end of the servo extension

lead (we like to tie this string tightly to the connector). With the

string in place to the connector, feed the connector and string into

the servo bay while gently pulling on the string at the exit hole in

the center of the wing. Start the connector down through the holes

in the wing ribs. Lightly pull back and forth until the connector

moves through one rib and up to another. Keep doing this until the

connector appears at the exit hole. Pull the connector up through

the hole and temporarily tape it to the wing surface. Now, mount

the servo hatch and servo in place to the bottom of each wing

panel, using the provided screws, removed earlier. Repeat this

procedure with the opposite servo hatch and wing panel.

❑

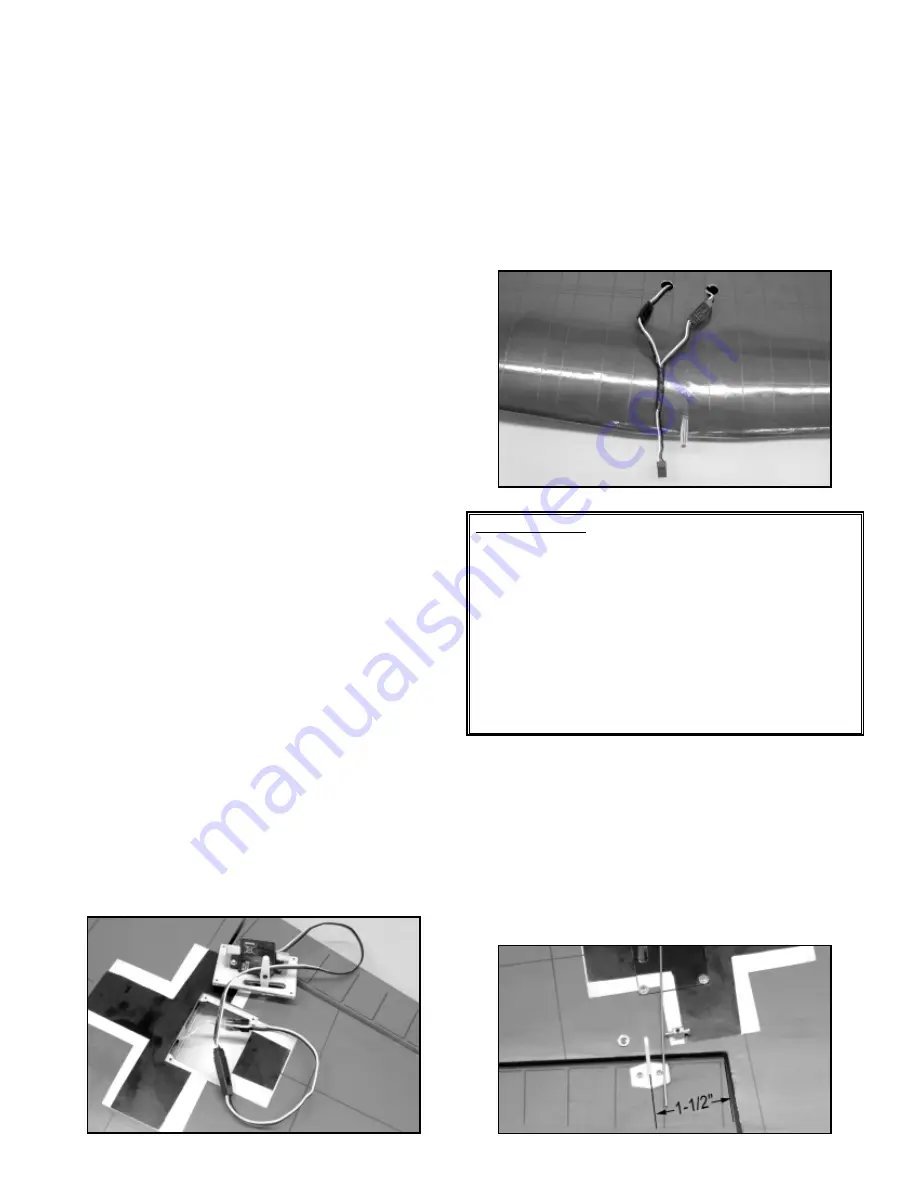

13) With both servo leads now through their respective exit

holes on the top center of the wing, remove the strings and plug

each lead into a standard "Y" harness.

Again, we suggest

securing these connections with short lengths of heat shrink

tubing.

❑

14) The aileron control horns are now installed onto the bottom

surfaces of each aileron. The vertical center arm of the control

horn is located 1-1/2" from the inboard from the end of the aileron,

with its four hole locations lined up with the hinge line. Hold the

control horn in this position and use a sharp pencil to mark the two

control horn mounting hole locations onto the surface of the

aileron.

At the two marks just made, use a #46 (2 mm) dia. bit to drill two

clearance holes completely through the aileron, 90

O

perpendicular

MODELER’S TIP: It happens to all of us now and then; the

factory installed servo lead string disappears into the wing! No

problem. Simply pull the string completely out of the wing and

attach a small weight, such as a metal nut or even a small split

shot sinker, to one end of the string. Insert the weighted end of

the string into the servo opening and start it down the holes that

are just behind the spars. With the wing on end and the center

of the wing below the servo well, gently shake the wing while

feeding the in the weighted string, listening for the weight to

drop through to the next rib.

When the center section is

reached, turn the wing upside down and shake the weight out

of the hole and you're back in business!