instabus EIB

Technical Product Information

April 2006

Touch panel UP 588

5WG1 588-2AB01

Touch panel UP 588/11

5WG1 588-2AB11

Touch panel UP 588/21

5WG1 588-2AB21

Accessories: Design frame, anodised aluminium

5WG1 588-8AB01

Technical Manual

UP 588, 6 pages

Siemens AG

Automation and Drives Group

Update: http://www.siemens.de/gamma

©

Siemens AG 2006

Electrical Installation Technology

Subject to change without prior notice

P.O.Box 10 09 53, D-93009 Regensburg

2.3.1.4/4

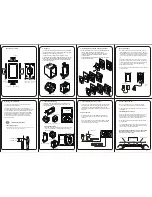

B1 Flush-type

box

B2 Opening for power supply cable

B3 Opening for bus cable

B4 Touch

panel

B5 Fixing

screws

B6 Design frame

B7 All-purpose

cover

Connecting the bus cable (Diagram 3 “A”)

−

The bus terminal (C3) is suitable for solid conduc-

tors with 0.6 ... 0.8mm Ø.

−

Remove approx. 3 cm of the insulation of the bus

cables.

−

Strip approx. 5mm of insulation from the conduc-

tors (C3.4) and place in the terminal (C3) (red = +,

grey = -).

Clipping on the bus terminal

−

Place the bus terminal in the guide slot and press

the terminal (C3) downwards until it reaches the

stop.

C3

C3.1

C3.3

C3.2

5 mm

C3

C3.4

C3

C3.4

"A"

C4.1

"B"

6....7mm

C4.2

C4

Diagram 4: Connections

Connecting the power supply terminal (Diagram 3 “B”)

−

Strip 6...7mm of insulation from the conductors

(C4.1), clip on the power supply terminals (C4) and

tighten the screws (C4.2).

Terminal assignment:

230V

24V

1

Earth

In1: +/- DC: AC

2 N

Neutral conductor

not connected

3 L Phase

In2: +/- DC: AC

After connecting the bus terminal and the power supply

terminal to the cables, the terminals are inserted in the

corresponding openings on the touch panel. Once the

bus voltage has been applied, the learning button can

be pressed and the physical device address can be pro-

grammed. The LED should be extinguished when the

physical address has been programmed.

The device is then screwed into the box using the four

screws supplied (see Diagram 2).

The protective foil that is attached to the surface of the

display may now be removed. No sharp objects or tools

should be used to do so.

After screwing the device into position and removing

the protective foil, the required design cover can be

inserted in the display frame. Finally, the all-purpose

cover is placed onto the display and latched in place,

thereby holding the design cover in position.

Caution:

Do not exert direct pressure on the display!

There is a risk of the glass breaking!

Once the installation is completed, the power supply

voltage can be connected to the supply and the device

can be put into operation (see the application program

description for information about programming).

Dismantling

-

First disconnect the power supply voltage from the

supply.

-

The all-purpose cover must first be removed when

dismantling the device or replacing the design

frame. The cover can be released at the openings

provided (D1) at the bottom using the dismantling

tool provided or a plastic screwdriver.

Caution:

When releasing the cover, only slight pres-

sure may be exerted on the display. Do not

damage the surface of the display with the

dismantling tool!