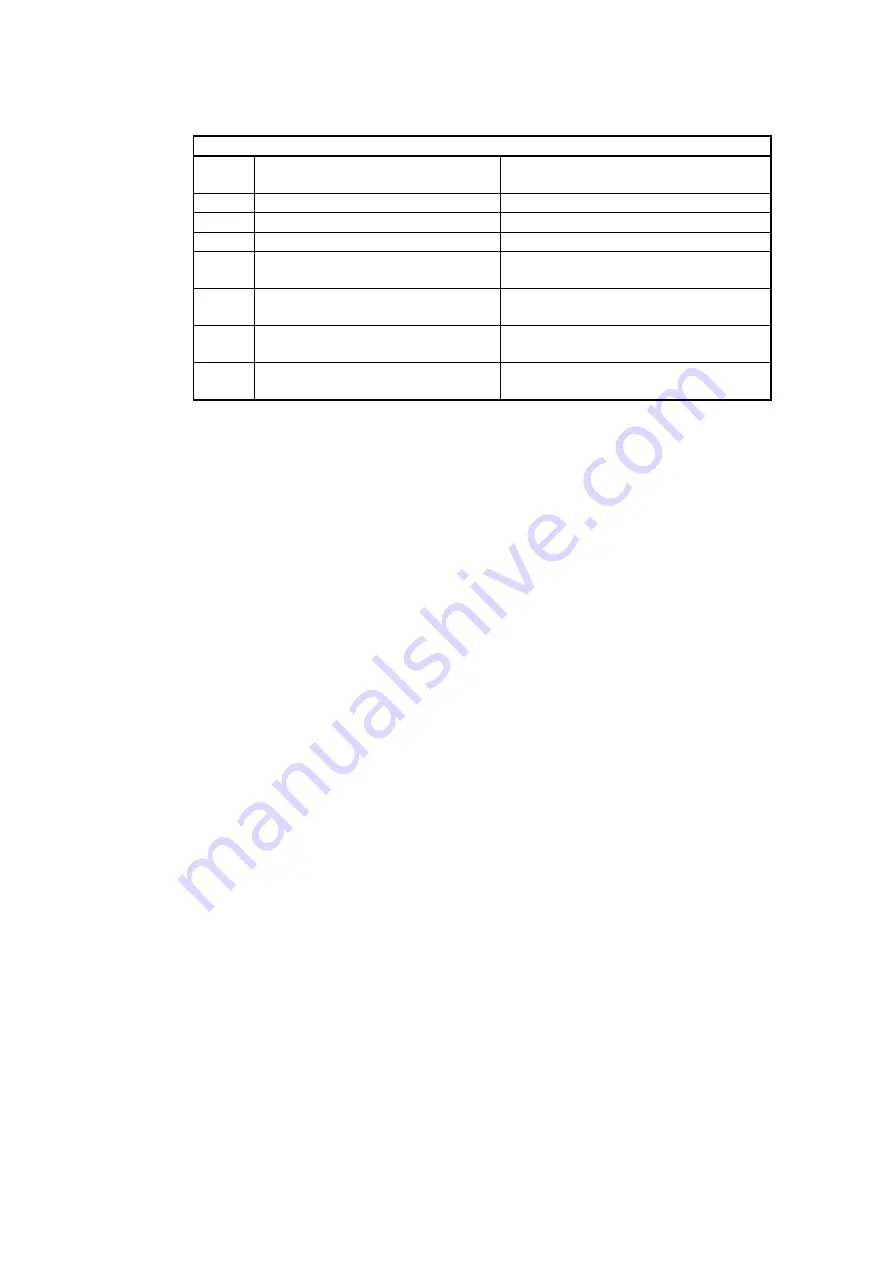

8BCOMMUNICATION WITH OTHER SYSTEMS

Channel 2

8 *)

Number n for reading DR(n) and DR(n+1)

Confirmation of number n for DR(n) and

DR(n+1) prepared for reading

9 *)

Number m for writing DR(m)

Status byte

10 *)

Still free

Current weight (H) (updated cyclically)

11 *)

Task controlling

Current weight (L) (updated cyclically)

12 *)

Variable (H) of DR(m) for writing

Current variable (H) corresponding to data

record number n

13 *)

Variable (L) of DR(m) for writing

Current variable (L) corresponding to data

record number n

14 *)

Default value for remote display 1 (H)

(transferred cyclically)

Current variable (H) corresponding to data

record number n+1

15 *)

Default value for remote display 1 (L)

(transferred cyclically)

Current variable (L) corresponding to data

record number n+1

*) for 2-channel module

Table 9-3

Assignment of the peripheral area

9.3 Reading data records from the module

The current weight values are automatically prepared cyclically.

In the area "Current variable" (4 bytes), only the selected data records are read.

Via the number of the data record to be read "n", it is determined which data

records are to be read from SIWAREX U. Here, the specified data record "n" and

the following data record "n+1" are always read and entered in the area "Current

variable".

Via "

Confirmation of the number n for DR(n) and DR(n+1) prepared for reading"

one

should now check whether SIWAREX U has already made available the requested

data records in the area "

Current variable corresponding to data record number n and

n+1"

. (Depending on the cycle time of the automation device, it can take several

CPU cycles before the requested data records are available). If the "

Number n for

reading DR(n) and DR(n+1)"

and the "

Confirmation of number n for DR(n) and DR(n+1)

prepared for reading"

are the same and if it has been established via the live bit that

the component is reacting, then the requested current data records are available in

the area "Current variable".

If a command or writing which changes the content of a data record to be read is

being executed prior to the reading of a data record, then the reading may only be

carried out when the instruction bit and instruction acknowledgement bit for the

writing are the same (i.e. no write task is running or the last write task has ended).

Example:

The command "Adjustment weight valid" affects the data record DR61 (adjustment

digits).

The data record should only be read out when the command has been completed.

When the "

Number n for reading DR(n) and DR(n+1)" does not change, the variables are

prepared anew every 20 ms by the module.

9-60

SIWAREX U

Summary of Contents for Siwarex U

Page 8: ......