04/99

Symbolic Addressing

Getting Started with C7-621-AS-i

47

Symbolic Addressing

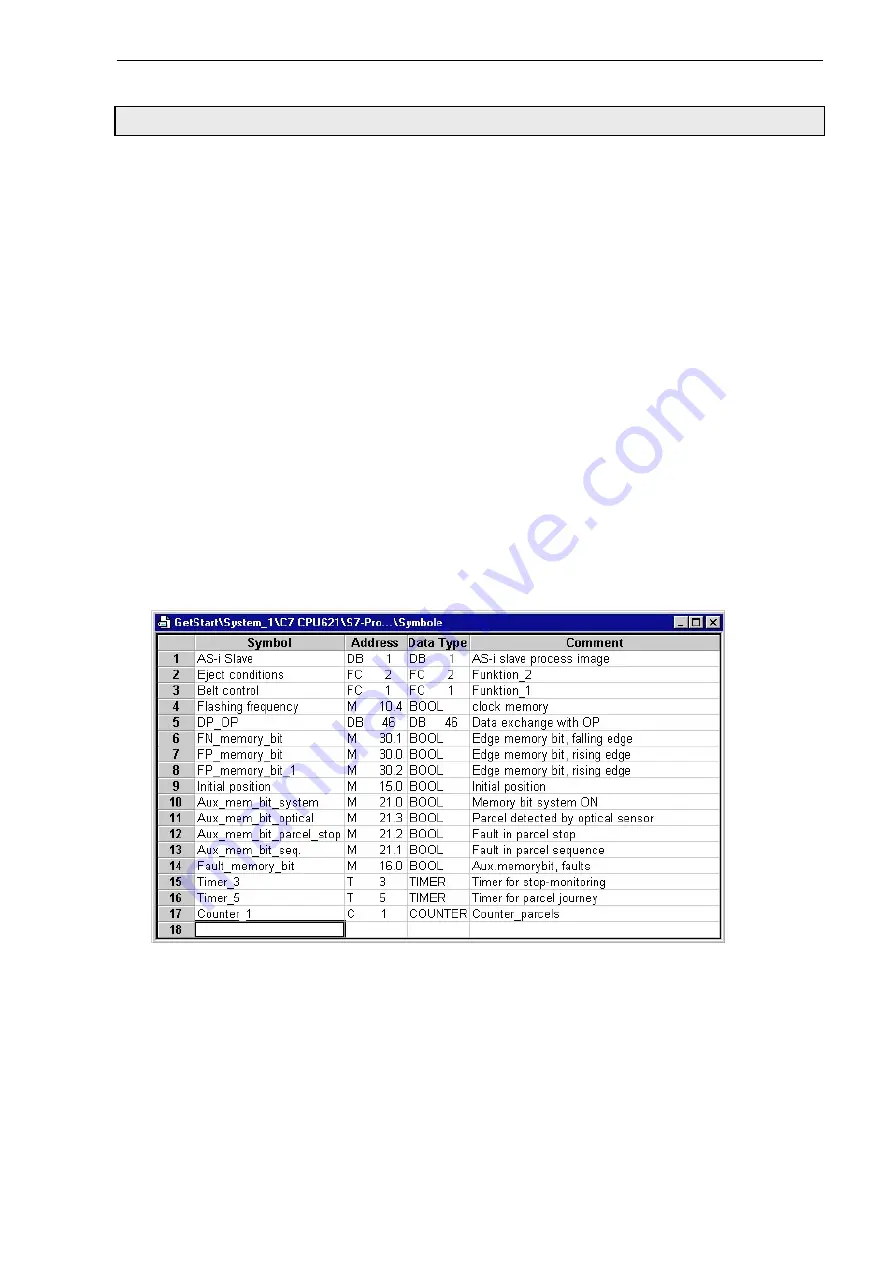

When programming with STEP 7 you work with operands such as I/O signals, bit memories, counters,

timers, data blocks and function blocks. So far you have addressed these operands in your program

absolutely (e.g. on DB46). However, it is helpful to assign symbolic names for them (e.g. on DB_OP, Belt

control). In the declaration section of the data block, you have already defined the symbolic alphanumeric

names for your data elements in the memory block DB1, and defined the DB1 via the structure of UDT1.

If the symbol name of the data block is accessed symbolically, this name must be entered in the symbol

list. This allows full symbolic access to a data element in the data block. To define the symbolic names,

proceed as follows:

In the SIMATIC Manager select in the

S7 Program(1)

folder the

Symbols

folder and open it with a

double click. The Symbol Editor with the symbol table is displayed.

In the symbol table, activate the first field in the

Symbol

column by clicking on it, and enter a symbol

name (e.g. DB_OP).

Jump to the

Address

column using the TAB key and assign an address (e.g. DB 46) to the symbol

name.

Skip the

Data type

column by pressing the TAB key twice. A default value (e.g. WORD) is

automatically entered for the data type and the

Comment

field becomes active.

Enter a comment in the comment field and press the TAB key again. The second field in the Symbol

column becomes active. Repeat the steps to enter additional symbol names. When you have

finished, save the symbol table and close the Symbol Editor.

Note

Although long symbolic names are more descriptive, they take longer to edit. With a combination of short

symbolic names and detailed comments, you can satisfy the requirements of both good program docu-

mentation and effective program creation.